Study on vegetable drying

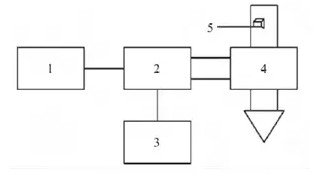

Microwave drying equipment is a common method in modern drying. It uses hot air as drying medium, uses heat sources (coal, petroleum, natural gas, etc.) to provide heat, and blows hot air into oven or drying chamber through blower to speed up air flow and transfer heat to materials. Water on the surface of materials is heated and vaporized and diffused into the surrounding air. In gas, when the surface moisture content of the material is lower than its internal moisture content and forms a moisture gradient, the internal moisture diffuses to the surface until the moisture content in the material drops to a certain extent; at the same time, the surface temperature of the material is higher than the material center after heating and forms a temperature gradient, which promotes the heat transfer from the surface to the center. In the drying process, mass transfer and heat transfer occur simultaneously and in opposite directions.

The hot-air drying of coriander was studied. It was found that the drying time of the blanched coriander was shortened obviously because of the long high-speed drying stage during the whole drying process; the higher the drying temperature, the greater the wind speed, the smaller the thickness of the packing layer, the higher the drying rate and the shorter the drying time; the higher the temperature, the wind speed and the paving time were. The rehydration of coriander dry products increased first and then decreased.

The effects of microwave drying temperature on the drying characteristics and color of celery were studied, and the drying model was fitted. The results showed that the higher the drying temperature was, the shorter the drying time was, but there was no significant effect on the color of celery; the drying process was mainly a slow-down stage, indicating that the internal moisture diffusion was the main control factor in the hot-air drying of celery; Page model could predict the hot-air drying process of celery; 60 C was the most suitable drying temperature, at which time, the drying process was controlled by the internal moisture diffusion. The time is short and the color is good.

The drying kinetics of unbleached and blanched spinach under different hot air drying temperatures and load densities was studied with constant air velocity. It was found that the drying rate increased with the increase of temperature and decreased with the increase of time; the effect of pretreatment and loading density on drying rate was not significant; Page model was the best model to describe the hot air drying process of spinach.

In order to calculate the effective moisture diffusion coefficient and drying activation energy of spinach microwave drying, the wind speed was constant at 1.2 m/s, and the hot air temperature was set at 50, 60, 70 and 80 degrees, respectively. The logarithmic model of spinach hot air drying was obtained. The effective moisture diffusion coefficient was (6.590 65507 .35 kJ/mol.

The hot air drying characteristics of coriander leaves at different drying temperatures and the influence of blanching on drying process were studied. The results showed that the hot air drying of coriander leaves was only at the stage of slow drying, and Page model was the best one to describe the drying of coriander leaves. The drying rate was obviously higher than that of blanching samples (P < 0.05), and the drying activation energies of unblanching and blanching samples were 26.5 kJ/mol and 24.6 kJ/mol, respectively. The Optimum Blanching Temperature was 80 C and blanching time was 3.

When min and drying temperature were 45 degrees, the chlorophyll retention of the product was the highest and the rehydration ability was the best.

The disadvantage of hot air drying is that the appearance of materials (such as color) and nutrient content deteriorate or degrade due to excessive drying temperature or longer drying time, and the thermal efficiency is low. However, due to its advantages of easy operation, easy control and low investment, it is still the most commonly used drying method of agricultural products. Therefore, according to the characteristics of the dried materials, to find out the suitable hot air drying conditions is the key to the hot air drying of green leafy vegetables.