Microwave drying characteristics and drying model of sweet potato chips

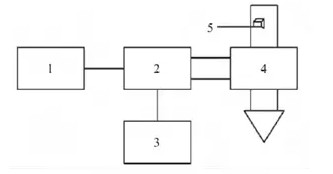

Abstract: The microwave drying equipment of the potato chips was studied. The microwave drying test factors of the potato chips were determined. The single factor test was carried out to analyze the loading, microwave power and slice thickness on the relationship between water content, water loss rate and power consumption. The effect of microwave drying characteristics on the film, the law of water loss in the microwave drying process of the potato chips was obtained.

The mathematical model of microwave drying of potato chips was determined. The DPS software was used to fit the experimental data, and the fitting equation which accorded with the microwave drying law of the potato chips was obtained. The statistical test showed that the fitting effect was very good.

Key words: sweet potato microwave drying; characteristics; model

Sweet potato is one of the traditionally cultivated food crops. It is rich in nutrients and enjoys the reputation of “nutrition and health food”. China's sweet potato has the highest annual planting area and total output, ranking first in the world. However, due to its high water content, perishable and dehydrated sweet potato, it has become a short-lived and difficult-to-preserve agricultural product.

Compared with the traditional drying method, microwave drying not only has high heat utilization rate, short heating time, saves energy, saves production cost, and can improve the eating quality after grain drying, and the drying process is easy to automatically control. Therefore, microwave technology has broad application prospects in food drying. In this study, the drying characteristics and drying model of the sweet potato were studied by microwave drying, and the microwave drying law was mastered to provide a basis for the industrial production of microwave drying of sweet potato.

Effect of Slice Thickness on Microwave Drying Characteristics of Sweet Potato

Weigh 120 g of different thickness potato chips and select 240 W for microwave drying. The total drying time required for microwave drying to a safe moisture content of 15 (wet basis) is about 45 min. As the thickness of the slice increases,

The dewatering rate decreased, and the drying time of microwave drying to safe moisture content increased, but the thickness of the slice had little effect on the moisture content of the drying process. During the drying process, the water content at the same time increases with the thickness of the slice, and the time required to dry to the same moisture content is also slightly longer.

Drying and dehydration of sweet potato is divided into three stages: accelerated drying stage, constant speed drying stage and slowing drying stage. The curves of each stage are obviously different. The accelerated drying stage has a short time, the curve is steep, and the water loss rate increases rapidly; the constant speed drying stage curve is gentle, the water loss rate no longer increases, and basically maintains a certain water loss rate, and the water content drops rapidly; In the fast drying stage, the curve drops rapidly and the rate of water loss decreases significantly.