Effect of Different Drying Methods on the Quality of Banana Products

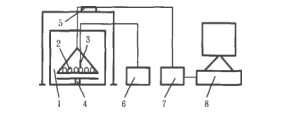

Abstract: In order to compare the common ingredients of hot air drying, vacuum freeze drying, traditional frying drying, vacuum drying, microwave drying equipment, temperature change, pressure drying and puffing drying, the nutrients, microstructure, sensory quality and flavor components of banana dry products. The impact of the production cycle. Physical and chemical analysis techniques were used to detect the content of nutrients; scanning electron microscopy was used to observe the microstructure; solid phase microextraction gas chromatography-mass spectrometry was used to analyze the flavor components; and the score method was used for sensory evaluation and comprehensive evaluation of coefficient of variation.

The results showed that the nutrient composition of banana products changed significantly under 6 different drying modes. The temperature-variation pressure difference puffing drying and vacuum freeze-drying could better preserve the various nutrients of the products. The scanning electron microscopy showed that the temperature and pressure difference puffed dry products had the largest cell gap, sensory The highest score was obtained. The results of solid-phase microextraction gas chromatography-mass spectrometry showed that banana products produced different kinds of flavor substances and unique flavor components in six different drying modes. The temperature change pressure difference puffing drying and vacuum freeze drying can better retain fresh An ester substance in bananas.

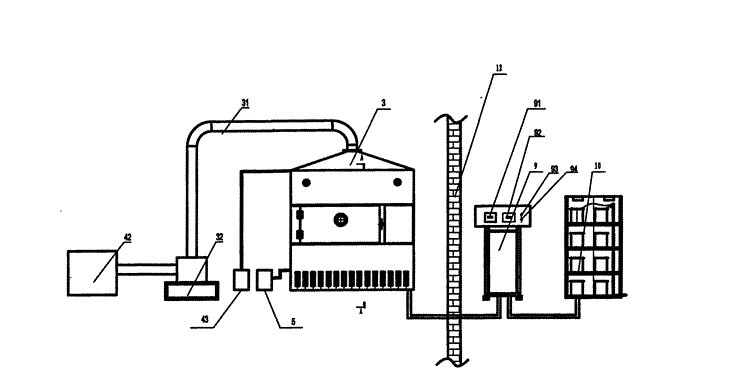

The comprehensive evaluation results of drying method are: vacuum freeze-drying> variable temperature differential pressure puffing drying> traditional frying drying> vacuum drying> vacuum microwave drying> ordinary hot air drying. However, the vacuum freeze-drying investment is large, and the production cycle is long; the variable temperature and pressure difference puffed and dried microscopic cell structure voids are the largest, giving the product a loose porous structure. Comprehensive consideration of product nutrition, sensory score, flavor material, microstructure, production cycle five types of evaluation indicators, variable temperature and pressure difference puffing and drying processing technology is suitable for the production and processing of dried banana products.

Key words: banana microwave drying; drying method; nutrient composition; microstructure; flavor component; coefficient of variation

Banana is rich in nutrients, rich in protein, carbohydrates, dietary fiber, trace elements, multivitamins and biologically active ingredients. It has the physiological effects of laxative, improving sleep and beauty. There are 130 countries and regions that grow and cultivate bananas around the world. China is rich in banana resources and its third largest producer in the world.

However, the phenomenon of slow-moving bananas in recent years has caused huge economic losses, which has seriously affected the enthusiasm of banana farmers. It is urgent to research and develop new technologies and new processes for banana processing and preservation, thus prolonging the storage period of bananas. Dry preservation is one of the best ways to preserve bananas. It is especially urgent to find a drying technology suitable for the industrial development of bananas.

Drying technology is an important unit operation technology in modern food engineering and is widely used in the processing of various foods. The principle of drying technology processing and preservation is to reduce the moisture content and water activity to achieve the purpose of inhibiting bacteria and inactivating enzyme activity, so as to better ensure the quality of the product and extend the shelf life.