Effect of Vacuum Microwave Drying on the Quality of White Shrimp

Abstract: The process of vacuum microwave drying of shrimps from Penaeus vannamei was studied. The effects of microwave power, pre-drying time and loading on the quality of shrimps were observed. Based on this, the hybrid orthogonal experimental method was used to further optimize the vacuum microwave drying of shrimps. condition.

The experimental results show that microwave drying equipment, microwave power, pre-drying time and loading have certain effects on the rehydration ratio, water activity, elasticity and sensory score of white shrimp, and the main order of influence is microwave power. The largest, the second load, the minimum pre-drying time. The most suitable vacuum microwave drying conditions are microwave power 500 W, loading capacity 100 g, pre-drying time 20 min, and the product has the highest sensory score.

Key words: microwave drying shrimp; quality

China is a big fishery country, and its total fishery production ranks first in the world for more than a decade. However, there is still a big gap between China's aquatic product processing industry and developed countries. The processing rate of aquatic products in developed countries is above 80%, while the processing rate of aquatic products in China is less than 30%, mainly due to the backwardness of China's aquatic product processing technology and production equipment.

Penaeus vannamei Boone, also known as the Penaeus vannamei Boone, is a nutritious, delicious, and economically valuable aquatic product. Compared with other aquatic products, P. vannamei has a muscular muscle and a thin shell of fat. Its muscle contains 0.29% crude fat, 21.57% crude protein and 1.52% crude ash. It is also rich in minerals such as calcium and phosphorus.

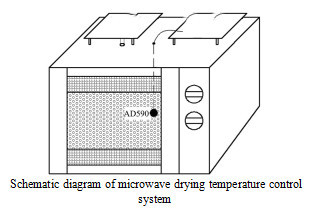

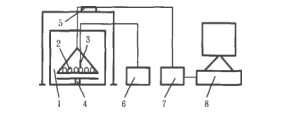

Vacuum microwave drying is a drying technology that uses microwave and vacuum to dry together. It not only makes full use of the uniformity of microwave drying, but also has the characteristics of rapid and easy control. It also uses water vapor to evaporate rapidly under vacuum conditions, which can better maintain food. Original flavor. At present, some scholars apply vacuum microwave drying to the drying of some aquatic products. Zhang Guofan and others used vacuum microwave to dry the scallop column and found that the product quality obtained by vacuum microwave drying is better than hot air drying and natural drying, and the microwave power and vacuum degree have a great influence on the quality of the scallop column.

Zhang Changsong and others studied the process of vacuum microwave drying of corrugated bark, and found that compared with hot air drying, the vacuum microwave drying speed is fast and the time is short, and the obtained product quality is high. Zhao Wei et al. studied the dynamics of vacuum microwave drying of P. vannamei and found that microwave power and loading have a great influence on the rate of dehydration of shrimp. In this experiment, the shrimps of P. vannamei were used as experimental materials to observe the effect of vacuum microwave drying on the quality of shrimps. The purpose was to explore the optimal process of vacuum microwave drying of shrimps.