Analysis on the Ways of Innovation and Development of Redwood Wood Drying Industry

Abstract: Combining the difficulties faced by mahogany furniture enterprises, the drying characteristics of mahogany wood and the characteristics of various drying processes widely used in the mahogany wood drying industry, the research results and direction of the wood microwave drying equipment industry and the status quo of the mahogany wood drying industry are analyzed. The innovative development approach of the mahogany wood drying industry was pointed out to provide a reference for the innovative and healthy development of the mahogany wood drying industry.

Key words: rosewood; wood microwave drying; innovative development

The traditional drying technology in the mahogany wood drying industry has high energy consumption, low efficiency, large pollution, easy to cause quality loss such as cracking and deformation of wood, and has been plaguing the majority of mahogany furniture enterprises. According to statistics from the China Wood and Wood Products Circulation Association, in 2017, China imported 981,100 m3 of mahogany logs and 148,000 m3 of mahogany sawn timber, totaling 1,129,100.

M3.

According to the wood loss rate of 5% of traditional wood drying equipment, about 56,000 m3 of redwood wood was lost due to drying in the whole year, and the direct economic loss was nearly 340 million yuan. With the implementation of the CITES trade ban on the Convention on International Trade in Endangered Species of Wild Fauna and Flora, the shortage of mahogany timber resources, the price of wood raw materials have risen sharply, and how the mahogany wood drying industry is innovating under the new situation is imminent.

The mahogany industry has its particularity. The mangrove species involved in the production and use of general enterprises are numerous and miscellaneous, and the batch size is small. It is difficult for enterprises to invest in large costs for drying wood, and old stale drying equipment is often used. Decentralized and extensive drying is not only restricted by equipment, but also by the lack of professional drying technicians. The lack of personnel and equipment has caused the quality and efficiency of wood drying, which in turn affects the promotion of corporate quality, and the company's profits are low, thus affecting the input of drying equipment and personnel, and entering an infinite loop. The situation of multi-purpose, chaotic, scattered, miscellaneous and small mahogany drying industry has seriously restricted the development of the entire industry.

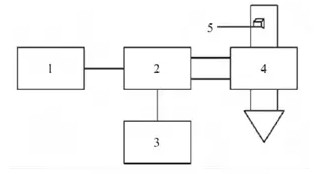

Today, the mahogany furniture industry is generally concentrated in industry gathering areas. Shen Mingqian et al. [16] put forward the problem of the homogenization of the industrial chain of the mahogany enterprises when analyzing the research on the Jiangsu mahogany furniture industry cluster. This is also a microcosm of the entire mahogany industry. There is a lack of cooperation mechanism among enterprises, and a lot of funds are used. Repeated investment in all aspects of the industrial chain. Integrating resources in the gathering area, creating a joint drying industry center, dispersing drying costs, improving drying quality, introducing new technologies and new equipment, and making it scale, specialization, intensification and systemization are the foundation of the benign development of the industry.