Effect of Different Drying Methods on the Quality of Mushrooms

Abstract: The mushroom was first cultivated in China and has a history of more than 800 years. It is the main edible fungus in Asia. China is the world's largest producer of shiitake mushrooms, Japan ranks second, and South Korea ranks third. Mushrooms contain high levels of water, polysaccharides, vitamins and other nutrients, but they are difficult to transport, store and process. Therefore, drying is one of the necessary processes before this.

As the largest export mushroom in China, the mushroom effect is related to China's export efficiency. By reviewing several drying methods of shiitake mushrooms and enumerating their respective advantages and disadvantages, the results show that microwave drying equipment is the most promising drying method for mushrooms and other fruits and vegetables.

Key words: mushroom microwave drying; drying method; quality analysis

Shiitake mushroom, also known as citron, sweet letter, flower mushroom, thick mushroom, mushroom, belongs to fungi, basidiomycetes, agaric, genus, and shiitake. The mushroom is rich in nutrients and delicious in taste. It is rich in amino acids, polysaccharides and vitamins. It is a low-fat, high-protein nutritional supplement, and is known as the “Queen of Mushrooms”.

Edible fungi contain high levels of water, polysaccharides, vitamins and other nutrients, but are not easy to transport, store and process. Drying is one of the necessary processes before this. As the largest export mushroom in China, the mushroom effect is related to China's export efficiency.

For a long time, the commonly used dried mushrooms in China have natural drying, hot air drying, far infrared drying, microwave drying, vacuum drying and vacuum freeze drying, as well as several drying methods. However, these methods are mostly limited to adjusting drying media. The temperature and flow rate cannot control the humidity of the drying medium. The heat pump drying studied in recent years can accurately and effectively control various parameters such as temperature, wind speed and humidity of the drying medium, and maximize the nutrient content of the product and its color, aroma and taste.

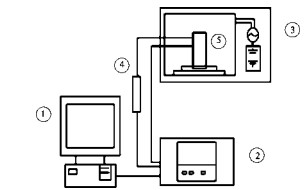

Microwave drying is to place the wet material in a high-frequency electric field. The high-frequency electric field constantly changes direction, so that the polar water molecules in the material vibrate at high frequency and rub against each other, and the inside of the material will rapidly heat up and heat, thereby achieving the purpose of drying the food.

The microwave drying speed is fast, and the fruits and vegetables are dried at the same time. However, microwave drying has one of the most common problems, that is, the material is unevenly heated, the surface of the material is easily burnt, and the microwave technology still has complicated equipment, is difficult to operate, and is expensive, and the unit consumes energy. Higher problems have largely restricted the promotion of microwave technology in the fruit and vegetable drying industry. Huang Jijun found that the microwave vacuum-dried lentinan content has a high retention rate of 5.8%; the sensory score of the mushroom is higher, and the sensory evaluation score is also Higher; microwave microwave drying process, the microwave vacuum drying process of mushroom can be divided into three drying stages: acceleration, constant speed and speed reduction according to the precipitation rate of mushroom body; the larger the microwave power, the greater the vacuum degree, the less the load is. The faster the dry precipitation rate, the shorter the drying time.

Huang Jijun et al. found that the microwave vacuum drying process of shiitake mushroom can be divided into three stages: acceleration, constant speed and speed reduction. The accelerated drying stage is shorter, and the constant-speed drying stage is mainly to remove free water between cells. The deceleration drying stage is mainly based on the removal of physical binding water. Microwave power and loading have a great influence on the drying rate of shiitake mushrooms. The drying rate is obviously accelerated with the increase of microwave power and the decrease of loading. The effect of vacuum on the drying rate is small. When the vacuum degree is > - 65 kPa, the effect of vacuum on drying time is not significant.