Study on the Key Technology of Preparing Purple Sweet Potato Powder by Microwave Drying Method

Abstract: The whole process of purple potato was prepared by microwave method. The effects of microwave drying equipment, calcium concentration, emulsifier addition and iodine blue value were discussed. The optimum conditions for the preparation of purple potato whole powder by microwave method were determined by orthogonal test. The microwave power was 539 W, the calcium immersion concentration was 0.075 ‰ and the emulsifier addition amount was 0.3%. The iodine blue value was 23.6. The processing characteristics of the whole purple potato powder were further determined.

The results showed that the water-holding capacity of purple potato whole powder was better than that of oil-holding. Under acidic conditions, adding sugar or salt could improve the gelling property of purple potato whole powder. Adding salt can also improve the whole powder gel. Freeze-thaw stability, the addition of sucrose has almost no effect on the freeze-thaw stability of the whole powder.

Key words: purple potato microwave drying; microwave method; processing characteristics

Purple sweet potato, also known as purple sweet potato, purple sweet potato or purple sweet potato, is a sweet potato with edible, medicinal and health effects. Its roots not only contain various nutrients of ordinary sweet potato, but also rich and strong. Antioxidant anthocyanins and anticancer effects of selenium.

Purple sweet potato powder is a granular, flaky or powdery dehydrated product obtained by drying fresh purple sweet potato, which can retain the nutrition and flavor substances of fresh purple potato, such as starch, dietary fiber, protein, sugar, fat, Ash, minerals, etc.

It can effectively solve the problem that fresh purple potato can not be developed due to seasonal, storage and transportation conditions. The finished product has low cell breakage rate, good physical properties, low viscosity, good dispersion and balanced rehydration, and can be used for a long time. It can be used as a raw material for the processing of various processed foods such as convenience foods, frozen foods, and conditioning foods. It can also be made into sugar, lactic acid, vitamins, citric acid and various whole powder derivatives.

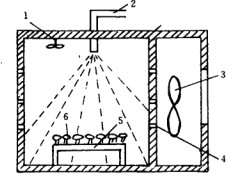

Therefore, the purple potato whole powder will be developed rapidly as the basic product of deep processing of sweet potato, and its market prospects in the international and domestic market are very broad. Due to the particularity of the wavelength, the microwave can be heated from the inside of the material to form a temperature gradient that is lowered from the inside to the outside. The moisture is gradually removed from the material along the high energy to the low energy, thereby achieving the purpose of drying. Microwave is widely used for the drying of vegetables and fruits because of its fast heating speed, short heating time, small footprint and high energy utilization.

At present, there are many researches on the preparation of potato granules by microwave heating and drying, but the microwave method is rarely used to prepare the whole purple potato powder. In this paper, the effects of microwave processing on the quality of purple potato powder are studied. It provides a basis for the application of microwave technology in purple potato processing.

The optimum process parameters for preparing purple sweet potato whole powder by microwave drying method were determined by orthogonal experiment, microwave power 539 W, calcium infiltration concentration 0.075‰ and emulsifier addition amount 0.3%.

On the basis of this, the processing characteristics of purple sweet potato whole powder were further determined. It can be seen that the water-preserving purple potato whole powder has better water holding capacity than oil holding capacity. Purple sweet potato whole powder can be used for the production of beverages, cakes and biscuits; Next, the addition of sugar or salt can improve the gelling properties of the whole purple sweet potato powder, and the addition of salt can also improve its freeze-thaw stability, while sucrose has almost no effect on the freeze-thaw stability of the whole powder.