Study on Optimization of microwave drying technology of anchovy fillets by Response Surface Methodology

Absrtact: Anchorage fillets were prepared with anchovy as the main raw material, and the processing technology of anchovy fillets was discussed. The technological process of anchovy fillet was determined as follows: freezing by flow hydrolysis, removing head, tail and viscera, pickling with 10% edible salt after cleaning, soaking with pepper water after rinsing in running water, drying naturally after vacuum pickling, then drying with oil temperature of 120-150 degrees C, drying for 12 minutes every 10 dm2120 g with microwave drying equipment of 3 kW. The syrup was packed in vacuum and sterilized at 121 C for 15 minutes.

Through sensory and texture shear tests, the optimum technological parameters of anchovy fillet were obtained as follows: 100g fish meat, 3G salt, 2G chicken essence, 5g spice powder, 5g pepper powder, 10g potato starch, 5g sugar, 0.1g delicious, 0.1g onion powder, 0.1g ginger powder, 10g yellow rice wine, 5g liquor. Under these conditions, the anchovy fillets are golden in color, crisp in outer layer, compact and chewy in meat, salty and slightly sweet, delicious in taste and good in taste.

Key words: anchovy fillet microwave drying; response surface methodology; microwave drying; texture

Anchovy is rich in carbohydrates, protein, fat, calcium, iron, phosphorus, zinc, selenium and other trace elements. Zinc, selenium and other trace elements play an important role in children's intellectual development. It was also found that abundant nutrients in anchovy can promote the increase of anti-infective lymphocyte in human blood. Medical clinical experiments also confirmed that anchovy can improve human tolerance to chemotherapy.

Microwave drying technology is a relatively novel drying method, which has been widely used in food, medicine and other processing and production fields. Compared with traditional drying methods, microwave drying technology has many advantages, such as easy automation, clean production process, uniform heating, easy control of product quality and high production efficiency. Because microwave drying technology has so many advantages compared with traditional drying method, microwave drying technology has attracted more and more attention in the field of food and medicine drying.

Cen Qiqiong and others have studied the application of different drying technologies in aquatic products processing, and the experiment proves that microwave drying technology has a good application prospect.

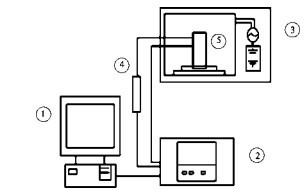

Microwave drying restructures the texture of anchovy meat, reduces water content and denatures protein, which makes the structure of anchovy meat tighten and hardness increase. The hardness of anchovy meat is measured by shearing test with texture analyzer, which reflects the change of structure, and thus measures the chewiness of anchovy fillets under certain drying conditions. Microwave dryer and texture analyzer were used to optimize the processing technology of anchovy fillets through response surface experiments, saving energy consumption and improving production efficiency.