Study on Microwave Drying Characteristics and Mathematical Model of White Pepper

Absrtact: Drying experiments of white pepper were carried out by microwave with power of 200, 400, 600 and 800 W, respectively.

The results showed that compared with the traditional drying technology, the time of microwave drying equipment was greatly shortened, but the white pepper after drying was easy to crack, the higher the microwave power was, the worse the quality was. The microwave drying model of thin layer white pepper was established by using three equations, and the results showed that the variables of the model based on Page equation had great correlation. The model is of great significance and the fitting effect of the equation is reasonable.

The sensory evaluation of white pepper products dried by different microwave power showed that the quality of white pepper products dried by microwave power became worse with the increase of microwave power.

Key words: white pepper microwave drying; drying characteristics; mathematical model; Page equation

Pepper is one of the most popular condiments because of its fragrance. In addition to condiments, pepper is widely used in food industry as preservatives and fresh-keeping agents; in medicine as stomach-strengthening agents, antipyretics, diuretics; in recent years, with the deepening of research on pepper utilization, pepper has also been used in pharmaceuticals, smoking cessation and drug addiction and military fields.

Chinese pepper processing is still primarily primary processing, the primary products are mainly white pepper, Hainan white pepper production accounts for about 98% of the total pepper production, production and processing are mostly workshop-based production, the traditional natural drying method is widely used, namely peeled pepper washed on the drying ground, generally need 2-3 days, the weather during drying and drying field. Hygienic conditions, easy to appear impurities and mildew problems, affecting the quality of white pepper and its trade quality.

Microwave drying has many advantages, such as high drying rate, energy saving, high production efficiency, uniform drying, clean production, easy to realize automatic control and improve product quality, so it has been paid more and more attention in various drying fields.

As early as the 1960s, the application and theory of microwave drying technology have been studied abroad, and it has been further developed in recent decades. The research of microwave drying technology in China started relatively late, and there is a certain gap compared with foreign countries, but it has also achieved good results. It has been used in food industry, material chemical industry, pharmaceutical industry, mineral mining industry, ceramic industry, laboratory analysis, wet natural rubber processing and so on.

With the gradual integration of China's economy with the international market and the development of agricultural industrialization, higher and higher requirements have been put forward for pepper drying efficiency, energy consumption and quality, flavor and nutrition after drying. It is urgent to continuously improve the economic benefits of pepper industry by using advanced drying technology.

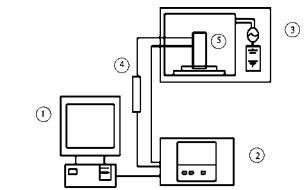

In order to quantify the relationship between microwave power, drying time and water loss, the microwave drying characteristics of white pepper were studied, and the drying regularity was discussed. The microwave drying dynamics model of white pepper was established to quantify the relationship between microwave power, drying time and water loss, and to provide theoretical basis for the production of microwave drying white pepper.

Under the experimental conditions, microwave drying of white pepper is prone to oil bract cracking and coking, and the greater the power, the more the number of oil bract cracking, the more serious the coking phenomenon, and the greater the impact on color. When the microwave power decreases, the acceleration period and the constant speed period are prolonged, and the drying speed is also slowed down. The sensory evaluation of white pepper products dried by different microwave power showed that the quality of white pepper products dried by microwave power became worse with the increase of microwave power.