Effects of different drying methods and inhibitors on wheat germ Browning

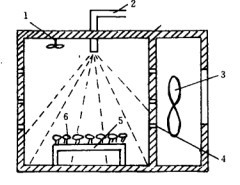

Abstract: The effects of microwave drying equipment, blast drying and far infrared drying on wheat germ browning were studied. The wheat germ was saccharified after drying, filtered and the absorbance at 430 nm was determined by spectrophotometer.

The color of wheat germ juice dried by far-infrared was the smallest. Orthogonal test was used to optimize the technological conditions of browning inhibition. The optimum technological conditions were blast drying temperature 50 C, ascorbic acid 8 mg, and treatment time 6 h.

Key words: microwave drying of wheat; far infrared drying; wheat germ browning; absorbance

The total yield of wheat in China ranks first in the world, and the annual total yield is about 1.10 *108 t. The storage capacity of wheat germ that can be exploited and utilized is as high as 280 *104~420 *104 t. Germ is rich in nutrients, crude protein content is more than other crops, iron, VB content is more, rich in amino acids, glutamic acid content is the highest, which is conducive to the improvement of children's intelligence.

However, at present, the research and development of wheat germ in China is still at the level of nutrient sources, and its function is far from being fully utilized. The main obstacle is its storage intolerance. Germ is very easy to be oxidized, which leads to rancidity and bad flavor. In addition, microorganisms are also very easy to reproduce and grow, so the stabilization of wheat germ is particularly important.

At present, the most widely used method to stabilize wheat germ is baking and drying. In addition to producing special colour and fragrance, the method can also destroy the original nutrients in the germ, such as amino acids, vitamins, etc. Even the production of carcinogenic substance acrylamide is related to Maillard reaction in the baking process. Therefore, it is particularly important to effectively control the drying conditions of wheat germ and prevent browning caused by Maillard reaction. By exploring various drying conditions, this paper aims to find the best drying method to inhibit browning, so as to create certain conditions for large-scale utilization of wheat germ and increase the utilization rate of wheat resources.

By comparing the chroma of the three drying methods, we can see that the lowest chroma of wheat germ obtained by far-infrared drying is the smallest among the three drying methods, followed by blast drying and microwave drying, and the chroma obtained by far-infrared drying is more stable and the average chroma is the smallest, followed by microwave drying and the average chroma obtained by blast drying. From the aspect of wheat germ color and drying efficiency, far infrared drying is more suitable than blast drying, but it has not been widely used in wheat germ processing industry.

The lowest chroma of wheat germ was 5.63 EBC when ascorbic acid was added to 8 mg and the treatment time was 6 h, which was 1.63 EBC lower than that of wheat germ without browning inhibition. The addition of ascorbic acid can inhibit the browning of wheat germ to a certain extent, reduce the color of wheat germ, and improve the extraction rate of pure wheat germ.