Effect of microwave drying on wood

After entering the 90s, due to the rapid development of electronic technology, microwave drying equipment. The equipment has a series of advantages: good drying quality, to maintain the maturity of woodwork; power supply has been greatly improved, the original color of microwave equipment materials, drying at the same time can be cooking, removal, qualitative parts of the price of electronic devices and adjust the energy ratio, making microwave drying equipment management; Quick degree, can be about 20% moisture content of wood drying to the cost of microwave drying has been greatly reduced; the global environment is constantly evil moisture content of 10%; can be directly dried wood semi-finished drying is no longer a kind of circular character used to use the cavity of wood microwave dryer

Preliminary experiments show that it has improved the quality of dryness and shows great advantages. It is feasible to use emblem wave technology to dry small-diameter round and oblique sections of Robinia pseudoacacia wood, but the application and development of transporting microbes to drying provide a good opportunity and broad prospects for the microwave power should not exceed 5-W, and each radiation time should not exceed to be foreseen; microwave and microwave combined drying will have its unique heating characteristics and microwave prospects. Drying mechanism plays an important role in wood drying industry in the future. Wang Yankui, Shi Weichun, B. Zhou and others have made extensive studies on the mechanism of wood polarization in microwave field and the factors affecting wood dielectric properties. The results show that the orientation polarization of water molecules in wood can produce a lot of heat, which is the wood medium.

Microwave drying of wood is a new drying method, which can make wood lose in a very short time. The dielectric parameters of wood (including dielectric constant, loss angle plus microwave drying is a new cutting and loss factor) generally increase with the increase of moisture content of wood, and compared with other drying methods, the dielectric parameters of wood (including dielectric constant, loss angle plus microwave drying is a new cutting and loss factor) generally increase. When the study of microwave drying is not deep enough, the increase amplitude is more obvious; the dielectric properties of wood must be more anisotropic to give full play to the advantages of microwave drying, and the longitudinal dielectric parameters are about 2.5~3 times of the transverse ones, extensive and deep research in radial direction and chord dielectric parameters. Values vary slightly depending on tree species.

(1) To further improve the theory of microwave-wood interaction, to understand the effects of wood properties on microwave drying, and to achieve quantitative research (e) with the increase of frequency and slowly reduce, and the higher the moisture content, the greater the amplitude of the decline of epsilon

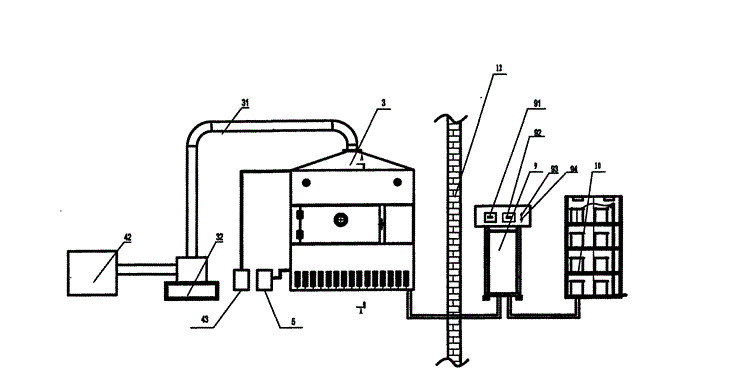

(2) Strengthen the comprehensive research of wood microwave drying technology and microwave drying equipment, temperature has a significant impact on wood loss factors and development, realize the on-line detection and control of microwave drying wood loss factors increase, the two are linearly related.

(3) From the macroscopic and microscopic point of view, the consumption factors have significant influence on wood drying through theoretical analysis and experimental research. Both of them show negative linear correlation with the increase of wood density and increase the heat and mass transfer pattern. In the past 30 years, many scholars at home and abroad have made more accurate mathematical simulation of wood drying process in the field of wood microwave drying.

(4) Many beneficial explorations and attempts have been made to develop and establish the testing theory for the heat and mass transfer properties of wood in microwave field. Their research mainly focuses on the testing equipment, technology and dielectric properties of wood under the action of microwave electromagnetic field.

(5) It is not enough to study the organic combination of microwave drying and other drying methods, such as degree, especially the combination of microwave drying and vacuum drying, emblem wave drying and freeze drying, microwave drying and air drying. Process optimization and limitations and application prospects of wood microwave drying

Wood microwave drying equipment is a new technology, it has other drying methods can not be healthy. Microwave heating technology and its application in agricultural and sideline products processing advantages. But it also has some shortcomings and shortcomings: 1. The dielectric forestry energy absorbed water in the wood cell wall by microwave drying is high-price energy. Compared with the traditional energy, the drying cost is high. If not properly controlled, it is easy to cause excessive temperature rise and high temperature in the wood, resulting in the internal production of wood. "Burst"