Combined drying test of hot air and microwave

Microwave drying equipment has a significant advantage in drying efficiency, and there is a certain difference in drying quality between microwave drying equipment and hot air drying equipment. Lu Weiqiao et al. analyzed the quality of ginger slices dried by microwave and hot air through scanning electron microscope. The results showed that the structure of ginger slices dried by microwave changed, the cell wall became confused under microwave, and mixed with starch granules. The change of structure would affect the rehydration ability and rehydration ability of the products. After the physical properties.

Microwave drying is the whole volume heating. If the water is not dispersed in time, the material will deteriorate due to overheating. Microwave drying speed is too fast, the final moisture content will be difficult to control, these technical defects to a single microwave drying challenges. Hot air drying at the beginning and the final stage can save energy and control the final state of the product. In the process of atmospheric pressure, hot air can effectively remove the free water from the surface of the material, and the dehydration process is mild and slow, which can ensure that the cytoskeleton of the material is not destroyed. The microwave drying process can accelerate the migration of moisture in the material. The combination of microwave and hot air in the middle stage can improve the working efficiency and drying quality

2.1 hot air atmospheric pressure microwave drying

Hot-air microwave drying under atmospheric pressure is to optimize the drying process combination by synergistic dehydration of internal and external materials with microwave and hot air. The drying time of carrot by microwave was shortened by 25%-90% compared with that without microwave, and the better drying quality was obtained at low power. The microwave combination drying of Agaricus bisporus can not only shorten the processing time, but also improve the product quality and rehydration ability.

Microwave drying of garlic showed that the drying time of microwave combined with hot air drying was shortened by 80%-90% than that of traditional drying, and good sensory quality was guaranteed. It was found that the drying rate and quality of fresh jujube were significantly affected by microwave power, material quantity and hot air temperature. Compared with microwave drying and hot air drying alone, hot air microwave coupled drying could obtain high quality products with fast drying rate, high VC content and good rehydration performance. The effect of hot-air microwave combination drying on spinach drying was studied. The results showed that hot-air microwave combination drying could maintain the quality of spinach and reduce the total number of colonies to a safe range.

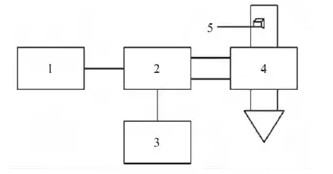

Hot-air microwave combined drying is a kind of hot-air microwave drying under atmospheric pressure. Compared with the combined drying, the combined drying method is more flexible. In the drying process, there are three kinds of microwave involvement, namely the initial stage, the slow-down stage and the low water content stage. In the initial stage, the material is heated rapidly, which opens the channel for moisture to migrate outward; in the deceleration stage, the surface layer of the material is dry and the moisture is concentrated in the interior. At this time, the microwave drying is applied, and the internal hot steam pressure is produced to make the moisture overflow to the surface and remove it quickly; considering that the material is difficult to expand because of the internal moisture when drying with hot air In the low water content stage, microwave heating can accelerate the outward movement of steam. The combination of hot air and atmospheric pressure microwave can improve drying efficiency and economy, and greatly shorten drying time without destroying the quality characteristics of final products. By optimizing the Microwave-hot air combined drying process of jujube, it was found that the quality of the dried jujube was good when the jujube was dried by microwave gap drying and then by hot air continuous drying.

However, drying with hot air and microwave also has shortcomings. At present, the conveyor belt is made of low-consumption microwave dielectric materials, and the materials are stationary on the conveyor belt, which is easy to cause poor moisture dissipation effect of materials in contact with the conveyor belt, and the improvement of microwave drying uniformity is limited.