Establishment of Microwave Drying Characteristics and Kinetic Model of Instant Mushrooms

Abstract: In order to improve the microwave drying equipment in the production process of instant mushrooms, the effects of microwave power and loading on the microwave drying of ready-to-eat mushrooms were studied. The microwave drying characteristics of ready-to-eat mushrooms were obtained. The effect of water content on the sensory quality of ready-to-eat mushrooms was discussed. The optimum moisture content of ready-to-eat mushrooms was obtained. The kinetic model of ready-to-eat mushrooms microwave drying was studied. The fitting data was fitted by DPS software, and the fitting equation which accorded with the microwave drying law of ready-to-eat mushrooms was obtained. The effect is good; it provides a theoretical basis for the production of ready-to-eat mushrooms.

Key words: ready-to-eat mushrooms microwave drying; sensory quality; kinetic model

Lentinus edodes is a fungus of the fungus medicinal fungus. It is a fungus of the genus Lactuca, which is also known as the mushroom, the mushroom, the citron, commonly known as the Chinese mushroom. In 2010, the output of shiitake mushrooms in China has reached 4.01 million tons. At present, in addition to fresh food, shiitake mushrooms are processed into snack foods, seasonings and functional foods and medicines.

The mushroom snack food is delicious and convenient to eat, and is favored by consumers. At present, it has been processed into mushroom candied fruit, mushroom puffed food and mushroom fluffy with the mushroom or mushroom foot, but the mushroom snack food accounts for a small proportion of the processed mushroom products. It is far from meeting the needs of consumers and has a broad market prospect. Instant mushroom is a ready-to-eat food of dried mushrooms, which is produced by rehydration, halogenation, drying, cooling, vacuum packaging, sterilization, etc. The drying process is an important part in the production process of instant mushrooms, which affects the taste quality of the products. And storage stability.

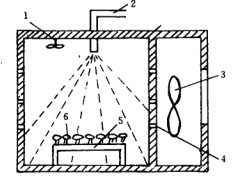

For the moisture content of the shiitake mushroom after baking, the moisture content of the mushroom is more than 80%. The flesh of the mushroom is soft and rotten, not tight enough, lacking elasticity, and the taste is poor, and the moisture is too high to shorten the shelf life of the product. Therefore, proper drying and dehydration treatment should be carried out; Drying technologies such as puffing, hot air and microwave have been applied to the development and research of various foods. These technologies have their own advantages, while microwave drying technology has the characteristics of high drying efficiency and less loss of nutrient materials. It has great potential in the food industry; Drying has been applied to the drying of fruits and vegetables such as Huaishan, Pleurotus eryngii and spring bamboo shoots. In this paper, the drying characteristics of ready-to-eat mushrooms microwave drying were studied, and a kinetic model was established to grasp the drying law and provide a theoretical basis for the production of ready-to-eat mushrooms.