Microwave drying characteristics and drying model of longan pulp

ABSTRACT: The effects of different microwave power density (P/m) on water ratio MR, water loss rate and drying time of longan pulp during drying were studied. The results showed that the microwave drying equipment of longan pulp was a slow drying process controlled by internal moisture diffusion.

Seven common food thin-layer drying models were used to fit the experimental data nonlinearly. By comparing the determination coefficient R2, root mean square error RMSE and chi square 2, the results showed that Midilli model was the best model for describing longan pulp microwave drying. The results show that the effective diffusion coefficient Deff increases with the increase of microwave power density. The value of Deff is between 0.7057 *10-9~1.8 *10-9 m2/s and the average activation energy is 1.266 W/g.

Key words: longan pulp microwave drying; drying characteristics; drying model

Longan cultivar is rich in resources and suitable for planting area. It is a special product with regional advantages. The traditional processing methods of longan are mainly dry, and the main drying method is hot air drying. However, there are some shortcomings in hot air drying, such as long production cycle, uneven heating of raw materials, unstable product quality and poor rehydration.

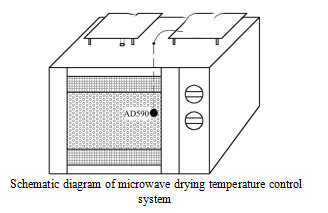

Microwave drying has many advantages, such as high efficiency, sensitivity, cleanliness, no waste heat and so on. Therefore, it has become a research hotspot in fruit and vegetable processing in recent years.

The microwave drying characteristics of longan pulp were studied by controlling microwave power density (P/m). The experimental data were fitted to select the best drying model. The effective diffusion coefficient and average activation energy under different power density were calculated. The drying process of longan pulp was analyzed, and the processing and equipment for longan pulp were set up. Provide reference.