Experimental study on microwave drying of Litchi

abstract

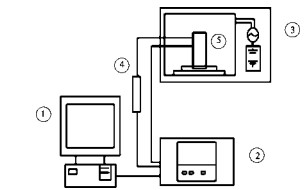

In order to explore the new technology of litchi microwave drying, a systematic experiment of litchi microwave drying was carried out by using a self-made microwave drying equipment test system. The water loss characteristics of litchi microwave drying were tested and analyzed. The distribution law of temperature in litchi pulp during drying process was found out. The influence of drying conditions on drying process was analyzed. The mathematical model of litchi microwave thin layer drying was established.

Keywords: microwave drying litchi, drying characteristics

Introduction

Litchi is a kind of high-quality and high-yield subtropical fruit with high economic value. Its fruit ripens in high temperature and humidity season. It should be treated in time after harvesting. Besides fresh food and preservation, a large number of dried fruits are produced. However, litchi drying is different from other fruits drying. Its pulp has high sugar content, high moisture content and is dry. Multi-structure structure structure, moisture migration after harvesting and heat transfer in drying process are complex, at the same time, it is not sliced with shell drying. Drying is in the state of internal control, and it is more difficult to dry.

At present, the methods used in Litchi drying still have the characteristics of long drying time, high energy consumption and unstable drying quality. Tunnel-type greenhouse drying equipment with air collector for natural air drying, which needs baking and brazing

In recent years, microwave heating and drying technology has been rapidly developed and applied. "But there is no literature report on litchi microwave drying at home and abroad. In order to apply microwave drying technology to litchi drying production." Based on the systematic microwave drying experiment of litchi, this paper discussed the drying characteristics of litchi microwave drying. The influence of drying conditions on drying process "was fitted to the test data by thin layer drying model.