Experimental study on microwave drying of longan

Absrtact: In order to explore the new technology of microwave drying longan, fixed power microwave drying experiments of longan under different heating and intermittent time combinations were carried out by using microwave drying equipment and self-developed computer on-line testing system.

The results showed that the microwave drying process of longan could be divided into three stages: acceleration, constant speed and deceleration drying. Most of the water loss process of longan was in the constant speed stage. Within 2.7-5 hours, the fresh longan fruit could be dried to the moisture content below 20%(w.b.) and the satisfactory drying quality was obtained. The microwave heating time had the greatest influence on drying speed. The effect of batch time is limited by heating time. In the later stage of drying, the heating time should be shortened to control the temperature rise of materials and avoid excessive drying. The regression equation based on experimental data can be used to describe the process of two-stage microwave batch drying of longan.

Key words: microwave drying longan; intermittent heating

Longan is a special fruit in southern China, which is rich in nutrients and has high economic value. However, longan has multiple tissues of shell, pulp and stone, and its pulp has high sugar content and high moisture content. Therefore, it is difficult to dry the whole fruit with shell. At present, the drying methods are mostly baking and hot air. It takes 6 to 9 days for drying method, 14 to 24 hours for continuous drying in tunnel drying room with 90 C hot air, and 6 days for Tunnel Greenhouse drying device with air collector. Long drying time, high energy consumption and unstable drying quality are the main problems in longan drying.

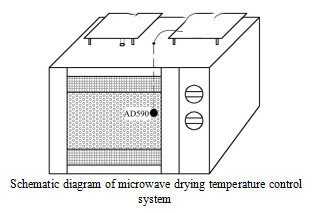

Microwave drying is suitable for the drying of spherical particulate matter because of its characteristics of uniform diffusion of internal and external moisture and fast drying speed. In recent years, microwave heating and drying technology has been applied more and more in food drying, but no report on longan drying has been reported. The feasibility of applying wave drying to longan production was studied. The effects of different drying conditions on the drying process were discussed through microwave drying experiments. The water loss and temperature characteristics of longan microwave drying were analyzed. The basic parameters were provided for the design of microwave drying equipment and the formulation of drying process.