Study on microwave drying of potato chips

Absrtact: The orthogonal experiment of microwave drying potato chips was carried out, and the water loss and power consumption characteristics of microwave drying potato chips were obtained. Regression analysis was carried out and the equation of microwave drying potato chips was obtained, which was better fitted by Page equation.

Key words: microwave drying equipment; potato

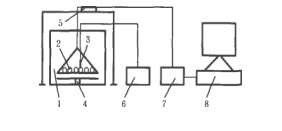

When traditional hot air drying different raw materials, the heating inside and outside of raw materials is uneven, energy consumption is large, time is long, and the drying effect is not ideal. The microwave drying equipment mainly uses the penetration characteristics of microwave. Microwave is a kind of electromagnetic wave, which can produce high frequency electromagnetic field. Polar molecules in dielectric materials change their polar orientation with the frequency of electromagnetic field, which makes molecules vibrate back and forth and generates friction heat. At this time, the field energy of electromagnetic field is transformed into heat energy, which makes the medium temperature rise continuously and has better drying effect. Using microwave technology to dry agricultural products is one of the developing trends in the future.

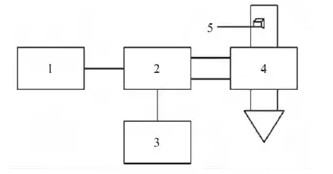

In this paper, the water loss characteristics of microwave drying potatoes are tested, the law of water loss and electricity consumption are obtained, and the mathematical model of microwave drying potatoes is established. The influence of drying process on quality after drying has a significant impact on the external quality. Higher initial emission power and lower later emission power are conducive to the improvement of external quality and quality. The larger the microwave power is, the local overheating will occur in the middle of drying, and even the phenomenon of sparking and internal scorching will occur. The quality of dry products.

For example, when the pre-launch power is 3.2 W/g, the post-launch power is 1 W/g and the pre-launch time is 8 minutes, the quality is the best; the bigger the slice thickness is, the worse the appearance quality is, because the smaller the slice thickness is, the shorter the drying time is, and the better the material appearance quality is; the higher the slice thickness is, the lower the rehydration ratio is; otherwise, the worse the slice thickness is. The higher the rehydration ratio is, this may be because the thicker the slices are, the more starch accumulates in the surface layer during drying, the hardening after gelatinization, the compact structure, and the water absorption of dry products is not easy; the thicker the slices are, the more round the shape of dry products is, the less the wrinkles are, the lower the rehydration ability of dry products is.

The loading capacity should be selected according to the capacity of microwave oven. It is reasonable to use thin layer drying to improve the quality of materials. To sum up, the best quality can be obtained with lower transmitting power (higher prophase transmitting power first), smaller chip thickness and reasonable loading capacity.

conclusion

(1) microwave drying potato chips can be divided into 3 stages: acceleration, constant speed and speed reduction.

(2) the thickness of slice increased and the rate of loss of water decreased, but the consumption of electricity increased.

(3) loading capacity increased, water loss rate decreased and power consumption increased significantly.

(4) power increased and water loss rate increased significantly, but electricity consumption declined little.

- the microwave drying equation of potato chips is better fitted by Page equation.