Research progress of other rapeseed drying technology

Due to the unique heating characteristics of microwave drying equipment, more and more attention has been paid to the processing of agricultural products and other fields. Microwave drying has the advantages of fast and uniform heating, good selectivity (faster heating in areas with higher moisture content), sensitive reaction, easy control and high energy utilization (mainly absorbed by the dried matter).

Lupinska et al. studied the microwave drying of rapeseed. It was found that microwave drying could sterilize rapeseed and produce less damaged seeds than hot air drying.

The feasibility of microwave drying rapeseed was studied, and the effects of microwave drying on seed value and quality characteristics were analyzed. It was concluded that microwave drying technology was feasible for rapeseed, which could not only dry rapeseed quickly and economically, but also maintain its seed value and improve edible quality, and had favorable variations, but could still be maintained later. Compared with hot air drying and far-infrared drying, microwave drying has the highest precipitation rate in constant-speed drying period, and microwave drying can enhance seed germination potential and improve the nutritional value of rapeseed.

Through microwave drying experiments of Rapeseed under different mass specific power, laying thickness and load cycle, the heat and mass transfer characteristics of rapeseed during microwave drying were analyzed. The results showed that mass specific power had a great influence on microwave drying rate, and suitable mass specific power, laying thickness and load cycle were beneficial to drying process. Conduct.

Hu Xiaohong and others used microwave heating technology to dry rapeseed, and then used gas chromatography and infrared spectroscopy to analyze the quality changes of the treated oil. The results showed that rapeseed with 11.85% water content could be reduced to 2.85% after 11 minutes by microwave heating, oil yield was increased after microwave treatment, fatty acid composition was basically unchanged and trans fatty acid did not exist, lipid peroxide value increased with the prolongation of treatment time, and microwave irradiation time had an effect on acid value and protein. The content of water had little effect on the content of water soluble protein.

High voltage electric field drying technology is a drying technology that arose in 1980s. Under high voltage direct current electric field, the evaporation rate of water is fast, the electric field energy consumption is low, and the drying material does not rise in temperature. Therefore, the drying products can be dried in a relatively low temperature range, and the retention rate of color, fragrance and biological active ingredients of the dried products can be greatly improved.

Development trend of rapeseed drying technology

Agricultural production in China is not concentrated enough. Artificial air drying and hot air drying are still the main means of rapeseed drying in the future. With the continuous reduction of non-renewable energy, the traditional drying method with high energy consumption will not meet the trend of social development. Energy-saving and efficient drying technology will always be the main direction of drying research.

Based on the research status of rapeseed drying technology, China should pay attention to the following aspects:

(1) Strengthen the basic theory of hot air drying of rapeseed, through simulation and analysis, optimize the process, further improve the drying efficiency of rapeseed and achieve "accurate drying".

(2) The drying technology of different kinds of rapeseed is not the same. Breakthroughs should be made one by one in the research. The mechanism research, mathematical simulation and process optimization should be carried out in a multi-pronged way, so that the drying technology of rapeseed has not only reliable theoretical basis but also wide practicability.

(3) Actively study new energy-saving, environmental protection and efficient drying technologies of rapeseed, such as solar energy and far-infrared catalytic drying technology, and try to scale up the new drying technology to gradually replace the traditional drying technology.

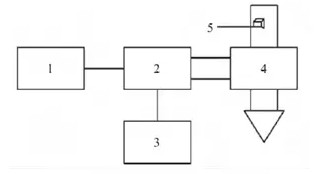

- Research and development of combined drying equipment, combined with two or more drying technologies, to improve drying efficiency and reduce energy consumption.