Effects of drying methods on quality characteristics of sweet potato leaf powder

[Abstract]

[Objective] To select the best drying method of sweet potato leaf powder, and to provide basis for enriching the varieties of sweet potato leaf products and prolonging shelf life.

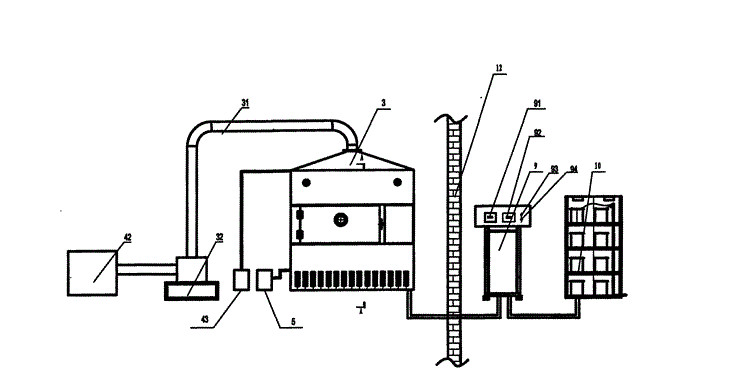

[Methods] sweet potato leaves were dried and pulverized by hot air drying equipment, microwave drying equipment, vacuum freeze-drying and spray drying. The effects of drying methods on the physical properties, microstructure and composition content of sweet potato leaf powder were studied, and the method of coefficient of variation weight was applied to the sweet potato leaves obtained by different drying methods. 4 methods were used to study the effects of drying methods on the physical properties, microstructure and content of sweet potato leaves. Comprehensive score of powder.

[results] the difference of color difference between vacuum freeze drying and spray drying sweet potato leaf powder was smaller, 3.98 and 3.86 respectively, showing better color; hot air dried sweet potato leaf powder had the highest bulk density of 0.76g / mL; spray drying sweet potato leaf powder had the lowest hygroscopicity, 10.05%; vacuum freezing. Dried and spray dried sweet potato leaves had smaller median diameter. The contents of total sugar and protein in spray dried sweet potato leaf powder were 218.71 and 27.85mg / g, respectively, which were significantly higher than those of other 3 drying methods (P < 0.05). The total phenol content and flavonoid content of vacuum freeze dried sweet potato leaf powder were the highest, 52.22 and 48 respectively. .46mg / G.

Under the 4 drying methods of hot air drying, microwave drying, vacuum freeze-drying and spray drying, the comprehensive score of sweet potato leaf powder was 0.684 - 0.275, 0.450 and 0.508 respectively. The best quality of spray dried sweet potato leaf powder was followed, followed by vacuum freeze drying sweet potato leaf powder.

[Conclusion] spray drying is recommended for sweet potato leaf powder drying.

[Key words] microwave drying of sweet potato leaf powder; drying method; quality; comprehensive score

Sweet potato leaves are also known as sweet potato leaves, sweet potato leaves and sweet potato leaves, that is, the young leaves on the top of the stem of sweet potato. Sweet potato leaves grow fast and have strong regeneration ability. They also contain protein, starch, vitamins, iron, calcium, flavonoids, chlorogenic acid and other substances. They have good health functions such as improving human immunity, promoting metabolism, delaying aging, protecting eyesight and preventing night blindness. Sweet potato leaves grow less pests and diseases, so the use of pesticides and fertilizers is very small, it is a natural green food. Sweet potato leaves, as a safe green vegetable, have a good diet function in life.

Sweet potato leaves have been listed as "space food" in the United States, as "longevity vegetable" in Japan and as "cancer-resistant vegetable" in Hong Kong. At present, most of the sweet potato leaves in China are treated as feed, and a few are used for making health wine, health tea and canned sweet potato leaves. However, the above requirements for storage, processing, transportation and other conditions of sweet potato leaves are high, which can easily cause the deterioration and loss of raw materials of sweet potato leaves. Therefore, it is very important to develop sweet potato leaves products which are easy to process and store, rich in nutrition and good flavor.

The dehydration and milling of fruits and vegetables can not only prolong the storage period, but also reduce transportation and packaging costs. Sweet potato leaf powder can retain most of its nutrients and facilitate storage and transportation. At the same time, sweet potato leaf powder can be added to noodles, pastries, solid drinks and other foods as raw materials to make people's daily intake of nutrients more balanced. The drying methods of fruits and vegetables are generally hot air drying, vacuum freeze-drying, microwave drying, spray drying and airflow puffing. Each drying method has its own advantages and disadvantages. The choice of drying method of fruit and vegetable powder must be determined according to the nature of the material.

At present, there are many studies on the preparation methods of sweet potato leaf powder, but there are few studies on the effects of different drying methods on the comprehensive quality of sweet potato leaf powder. Song Zhen and other researchers have studied the effects of hot air drying, spray drying and vacuum freeze-drying on the physical properties of sweet potato leaf powder. The best drying method of sweet potato leaf powder was spray drying. However, this study did not combine with the changes of nutrient components in the drying process of sweet potato leaf powder.

In this study, sweet potato leaves were taken as the test materials. Hot potato drying, microwave drying, vacuum freeze-drying and spray drying were used to prepare sweet potato leaf powder in 4 ways. The effects of different drying methods on the physical properties, microstructure and nutrient contents and contents of sweet potato leaf powder were studied in order to screen the best way to dry sweet potato leaf powder. It provides basis for commercial production of sweet potato leaf powder.