Microwave vacuum drying characteristics and drying technology of Chinese chestnut

ABSTRACT: The effects of microwave intensity, chamber pressure and other parameters on mass and heat transfer during chestnut drying under microwave drying equipment were studied. Box-Behnken central combination experiment design was used to determine the optimum parameters of microwave power, pressure and drying time in the process of microwave vacuum drying of chestnut, taking moisture content and whiteness as evaluation indexes.

The results showed that the microwave vacuum drying process of chestnut was mainly accelerated and decelerated, and the duration of constant-speed stage was shorter. Microwave power and vacuum degree have significant effects on drying time. The higher the power, the higher the vacuum degree and the faster the drying rate. The moisture content and moisture ratio of dry base gradually decrease with the extension of drying time. According to the regression model, the optimum microwave vacuum drying parameters of chestnut were obtained as follows: time 12 min, pressure 56 kPa and power 3 kW.

The microwave power, chamber pressure and drying time of microwave vacuum drying all affect the quality of chestnut. The drying parameters obtained from the model can ensure the quality of chestnut after drying, and the drying efficiency is high and the energy consumption is low.

Key words: chestnut microwave vacuum drying; drying characteristics; technological parameters

Castanea mollissima blume, also known as chestnut and Chinese chestnut, belongs to chestnut of Fagaceae. Fresh chestnut is prone to germinate and mouldy during storage and transportation. It is not suitable for long storage. Dehydration is needed in deep processing of chestnut. Chestnut belongs to heat sensitive material. Drying dehydration treatment has great influence on its sensory and nutritional quality.

Drying is an important food processing method and an effective way to prolong the shelf life of fruits and vegetables. It can reduce the weight, volume and transport of fruits and vegetables without adding preservatives. It is easy to eat and preserve for a long time. At present, the main methods of dehydration and drying of fruits and vegetables are hot air drying, microwave drying, heat pump drying and vacuum freeze drying. Hot air drying as a traditional drying method, due to long drying time and high treatment intensity, leading to browning of dry products, obvious reduction of characteristic flavor and other quality deterioration problems.

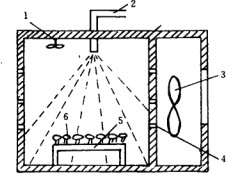

Microwave vacuum drying is a low-heat drying method developed rapidly in recent years. It is a high-tech combined drying technology using microwave energy for material drying under vacuum conditions. It has the characteristics of high drying efficiency, low temperature, easy control and environmental protection. Especially for materials which are difficult to achieve by traditional drying process, it can be very good. Retaining the original color, fragrance, thermal sensitivity and bioactive ingredients of materials, overcoming the shortcomings of hot air drying, the product quality is significantly improved than that of hot air drying, and is close to freeze drying. It is most likely to replace freeze drying in food drying, and can greatly reduce production costs.

Microwave vacuum drying is a low-heat drying method developed rapidly in recent years. It is a high-tech combined drying technology using microwave energy for material drying under vacuum conditions. It has the characteristics of high drying efficiency, low temperature, easy control and environmental protection. Especially for materials which are difficult to achieve by traditional drying process, it can be very good. Retaining the original color, fragrance, thermal sensitivity and bioactive ingredients of materials, overcoming the shortcomings of hot air drying, the product quality is significantly improved than that of hot air drying, and is close to freeze drying. It is most likely to replace freeze drying in food drying, and can greatly reduce production costs.

At present, microwave vacuum drying of apples, strawberries, grapes, kiwifruit, abalone mushrooms, carrots, garlic, tremella and other fruits and vegetables has been carried out at home and abroad. Cao Xiaohong studied the characteristics of microwave drying of chestnut and its quality changes after drying. Zhou Jie and others studied the microwave drying technology of chestnut, but the high temperature during drying seriously affected the quality of products. The application of microwave vacuum drying technology on Chinese chestnut has not been reported.

Because the changes of physical, chemical and sensory quality are closely related to the process of heat and mass transfer in drying of heat-sensitive materials, the characteristics of heat and mass transfer are different in drying process of different materials, and the effects of drying parameters on the quality of different materials are also different. In this study, microwave vacuum drying technology was used to dry chestnut slices. The effects of microwave power and vacuum degree on the drying characteristics of chestnut slices were investigated, and the optimum drying parameters were determined, which provided theoretical basis for the development of chestnut deep processing industry.