Ventilation improves microwave continuous drying uniformity of germinated brown rice

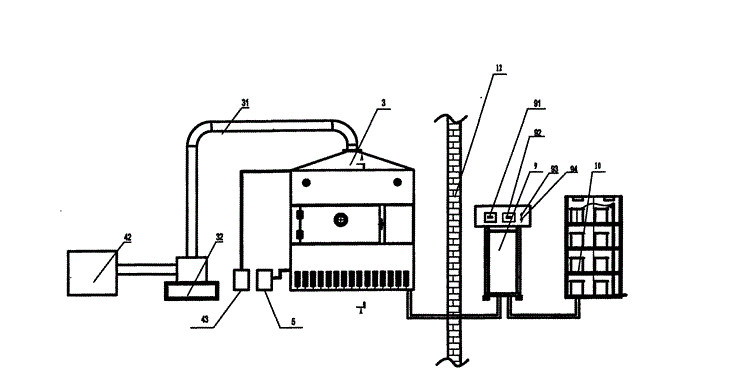

Abstract: In order to improve the uniformity of microwave drying of germinated brown rice, the combination of bench test, computational simulation and theoretical analysis was used to analyze the distribution of microwave energy in the inner layer of microwave dryer, and the wind speed was dried on germinated brown rice during microwave drying. Uniformity effect.

The results show that there is wear and reflection between the feed ports on the microwave dryer with parallel waveguide feeds, and the microwave energy utilization rate is reduced. In the microwave drying process, the room temperature air is taken away to remove the water vapor evaporated from the germinated brown rice: low wind speed The water vapor capacity is weak, and the high wind speed will result in uneven airflow distribution, and the suitable wind speed is 0.5~1.0 m/s.

The introduction of ventilation during microwave drying can improve the uniformity of microwave drying and solve the problem of poor uniformity of drying due to electric field distribution from the drying process. The research results provide a basis for the drying chamber structure design and drying process optimization of the microwave dryer.

Key words: electric field; germinated brown rice microwave drying; ventilation; uniformity

Introduction

The germinated brown rice is brown rice, which is germinated to a bud length of 1 to 2 mm at a suitable temperature and humidity. The obtained brown rice product consists of a young shoot, a layer of mash and an endosperm. The germinated brown rice contains various active ingredients such as γ- Aminobutyric acid, inositol hexaphosphate, and the like. The initial moisture content of germinated brown rice exceeds 30.0% (wet basis), and it should be dried as soon as possible to a moisture content of 15.0% (wet basis) to avoid deterioration of nutrients, deterioration of odor, etc., and to ensure the appearance of germinated brown rice. The color is normal. Microwave drying has the advantages of high efficiency and easy control, but uneven microwave drying is a key issue affecting the drying quality and energy utilization of materials.

The main factors affecting the uniformity of microwave drying are: microwaves are transmitted in such a way that the electric field and the magnetic field are perpendicular to each other. The arrangement of multiple magnetrons in the microwave dryer will cause the electric field to be superimposed, resulting in uneven distribution of electric field on the layer; drying chamber The structure affects the oscillation mode and electric field distribution of the microwave; during the drying process, the dielectric properties of the material change with increasing temperature and water content, resulting in selective microwave heating. The electric field and the uneven heating are present in the microwave dryer, so that the temperature distribution "cold spot" and "hot spot" in the material layer alternately appear, resulting in a large difference in moisture content of the material after drying.

The existing research solves the problem of microwave drying unevenness from two aspects of equipment and process: in the development of microwave drying equipment, optimize the key devices such as magnetron arrangement and drying chamber structure, improve the microwave energy utilization rate and the electromagnetic wave evenly distributed on the material layer. When designing the microwave drying process, according to the microwave drying characteristics of the material, the speed of the material is controlled, the slowing section is added, and the ventilation is introduced to improve the uniformity of temperature and water distribution.

However, in the microwave drying process based on the microwave energy absorption characteristics of the material, the research work lacks systematicity. Therefore, the microwave drying process has problems such as poor adaptability and unstable product quality; in the microwave drying of germinated brown rice, the moisture and temperature uniformity is poor. The problem seriously affects the quality of the product. Due to the lack of research on the theory of microwave energy absorption in germinated brown rice, the basis for solving the problem of microwave drying unevenness of germinated brown rice is insufficient.

In view of the above problems in the microwave drying process and the need to meet the high-quality production of germinated brown rice, the following research contents are proposed:

1) Analysis of the causes of the uniformity of microwave energy distribution on the germinated brown rice material layer in the microwave dryer

2) Study on the effect of ventilation speed on temperature and moisture of germinated brown rice in microwave