Effect of Different Drying Methods on the Quality of Crayfish

Abstract: In order to explore the effects of different drying methods on the quality of crayfish after drying, the crayfish were dried by hot air drying, microwave drying and hot air-microwave drying. The effects on physicochemical properties and sensory quality were studied.

The results show that the combined dry crayfish have higher L* value and a* value, better chewiness, lower TVB-N value and TBA value, color and flavor than hot air drying and microwave drying equipment. The sensory qualities such as taste are also the best. Hot air-microwave combined drying is an ideal method for drying crayfish.

Key words: crayfish microwave drying; quality

Crayfish, also known as Procambarus clarkii, is a crustacean that is now found in many parts of China and has become an important resource in freshwater shrimp in the middle and lower reaches of the Yangtze River. At present, the processing products of crayfish are mainly fresh cryogenic cryopreservation products and mature cryogenic cryopreservation products. The processing, storage and transportation of these products need to maintain a cold chain, and the cost is high, which limits the further development of the market.

Dried shrimp is a dried product of shrimp. Due to the large amount of water removed during the drying process, the dried shrimp can be stored at room temperature for a long time, and a special attractive fragrance can be formed during the drying process.

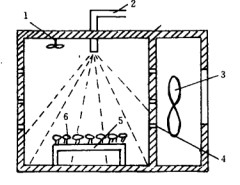

Hot air drying is currently a dry method commonly used in aquatic products. It has a large processing capacity and is easy to operate, but the treatment time is long, the active ingredient loss is large, and the quality is poor. The microwave drying rate is fast and the time is short, which can better preserve the color, fragrance and taste of the food, and reduce the nutrient loss of the material during the drying process; however, the microwave drying temperature is high, and the burn phenomenon caused by overheating is easy to occur.

Hot air-microwave combined drying refers to a composite drying technology that combines microwave drying and hot air drying according to the characteristics of materials. The composite drying technology is carried out in stages, which has the advantages of fast drying rate, good product quality, easy adjustment and control.

The drying method has a great influence on the quality of aquatic products. This paper compares and analyzes three kinds of drying methods: hot air drying, microwave drying and hot air-microwave drying. The color, texture, hygroscopicity, TVB-N of crayfish

The influence of TBA and sensory quality, in order to provide theoretical guidance and technical support for the selection of suitable drying methods for the preparation of crayfish shrimp.