Uniformity of microwave drying of carrot slices

Abstract: drying uniformity is one of the important indicators that affect the drying quality of products. The Drying Uniformity of carrot slices under different conditions was studied by dispersing microwave and moving materials in microwave chamber. Single factor experiments were carried out to study the effects of microwave agitator fan speed, material rotating speed, microwave power, microwave drying equipment and carrot quality on drying uniformity.

The results show that the drying uniformity can be reduced by increasing the rotational speed of the microwave stirring fan and the rotational speed of the material turntable; the drying uniformity will be aggravated by increasing the microwave power, and the final product quality will be affected; the drying uniformity will be affected by different material quality under the same shape. The results provide a basis for improving the microwave drying uniformity of carrot slices.

Key words: carrot slices microwave drying; Drying Uniformity

Carrot has high nutritional value, rich in lipophilic (carotenoid, lutein) and hydrophilic (polyphenol) antioxidants, and has many health functions. Food drying is an important means of food preservation, and is also an important food processing technology. Drying can reduce water activity and prolong shelf life. At present, infrared drying, hot air drying, freeze drying, ultrasonic and vacuum combined drying, and pectin coating technology can be used to extend the shelf life of carrots. Microwave drying technology is widely used in food processing.

Compared with traditional drying technology, microwave or microwave-assisted drying can improve the quality of food, maintain the nutritional components of materials, increase the color retention of food, reduce the degree of drying shrinkage of food, and enhance the ability of food rehydration. At the same time, because microwave drying rate and energy consumption are low, it shows high economic efficiency. However, the uniformity of microwave drying is one of the main problems restricting its large-scale application. The uneven drying of materials will cause some of them to be coked and some of them not dehydrated, which will seriously reduce the quality of materials and even cause food safety problems. Especially in industrial production, the problem of uniformity of drying is particularly important.

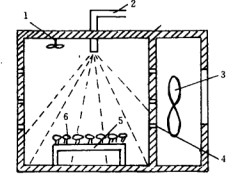

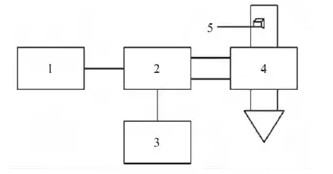

In this paper, the effects of Microwave Dispersion and different motion modes of materials in microwave chamber on drying uniformity were studied. The effects of microwave stirring speed and material rotating speed in microwave chamber on drying uniformity were analyzed. The effects of microwave power and material quality on drying efficiency were also discussed. The experimental results can provide technical reference for improving the uniformity of carrot slices in microwave drying and optimizing the uniformity of microwave drying.