Analysis of electric field intensity distribution in germinated brown rice microwave drying

Abstract: In order to improve the microwave energy utilization rate of the continuous microwave dryer and the drying quality of the germinated brown rice, the electromagnetic field simulation software HFSS is used to analyze the installation mode of the magnetron waveguide (horizontal, vertical, etc.) and the transition between the interior and the surface of the drying chamber ( The right angle and arc) affect the transmission and distribution of electromagnetic fields in the drying chamber, and optimize the installation position of the material conveyor belt in the drying room.

The results show that the installation mode of the magnetron waveguide of the continuous microwave dryer and the transition form between the six boundary surfaces in the drying chamber have significant influence on the uniformity and strength of the electric field distribution. The position and installation form of the output tube of the magnetron are germinated on the conveyor belt in the drying chamber. Brown rice has the most significant impact.

The longitudinal direction of the magnetron waveguide and the drying chamber of the right-angled microwave dryer have higher microwave energy utilization and uniformity of microwave field distribution. The research results provide a theoretical basis for improving the uniformity of microwave drying germinated brown rice and controlling drying temperature.

Key words: germinated brown rice microwave drying; waveguide; electric field strength, simulation

Germinated brown rice is rich in nutrients such as γ-aminobutyric acid, inositol and vitamins. In order to meet the nutritional and health needs of consumers, the quality index after drying becomes a concern for the drying process and equipment development of germinated brown rice. The germinated brown rice is obtained by wet germination of brown rice. The initial moisture content exceeds 30.0% (wb), the germination temperature of brown rice needs to be higher than 30 °C, and the short-term drying rate is below 15.0% (wb), otherwise nutrient degradation, odor, etc. Quality deterioration. Therefore, drying efficiency and productivity are key performance indicators for germinated brown rice drying equipment. Widely used in the drying of agricultural products. With the deep research of electromagnetics, materials science and other related disciplines and the new requirements of users for microwave equipment, the optimization design of microwave dryers is the research focus.

At present, the optimization design of microwave dryers mainly focuses on two aspects:

1 The simulated microwave energy is distributed inside the dryer to improve the uniformity of microwave radiation, and optimize the structure and shape of the drying chamber of the microwave dryer. Wang Mingxiang used HFSS software to simulate the influence of the position and number of waveguide ports on the electromagnetic field distribution inside the rectangular cavity. Determining the multi-waveguide symmetry setting can effectively improve the uniformity of electromagnetic field distribution in the cavity, and design a symmetric hexagonal microwave cavity. Study the matching problem between magnetron and waveguide, waveguide and cavity, reduce the loss of microwave transmission, so as to improve the effective utilization of microwave and avoid sparking and breakdown damage caused by improper microwave reflection.

2 According to the drying characteristics or quality requirements of materials, aiming at improving the utilization rate of microwave energy and uniformity of distribution, a microwave drying system suitable for certain materials is developed. According to the process requirements and dielectric properties of the caramel pigments (dielectric constant, dielectric loss factor and penetration depth), Wang Fei has more modes in the cavity of the microwave drying equipment, and the ratio is simpler and less. The high waveform factor is the optimization target, and the size of the microwave drying cavity suitable for caramel color is determined. The uniformity of material temperature during drying is high, and the drying quality meets the requirements.

For the pill and other materials, the dehydration speed is too fast and easy to crack, and it needs a certain humidity environment to dry. Zhang Yanyan designed a multi-layer continuous microwave pill drying equipment. The dehumidification system adopts the bottom air inlet and the top suction mode of the equipment outlet, so that the cooling air is inside the equipment. "S" type exercise effectively improves the drying effect of the pills.

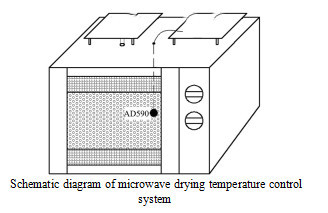

Microwave heating belongs to the body heating method, which leads to uneven drying of materials and high drying strength, which causes the quality of agricultural products to deteriorate, such as rice cracks and discoloration of fruits and vegetables [8]. There is a microwave dryer germination brown rice drying test, only 30% of the microwave output power is used for germination brown rice heating and drying to remove water, affecting the quality and efficiency of microwave drying germinated brown rice. The transmission mode of microwave in the drying chamber is one of the main factors affecting the utilization and absorption of microwave energy. Different magnetron arrangement and drying chamber structure have an important influence on microwave energy absorption.

In this paper, computer simulation technology is used to simulate the different structure and microwave input power of the drying chamber of germinated brown rice microwave dryer, simulate the electric field distribution on the conveyor belt layer in the drying room, calculate the percentage distribution of electric field intensity, analyze the distribution law of electric field intensity in the microwave dryer, and determine the most Good magnetron waveguide arrangement and drying chamber structure.