Advances in research on effects of drying methods on flavor and substance of fruits and vegetables

Abstract: In recent years, China's fruit and vegetable processing industry has developed rapidly. The process of removing fruits and vegetables has become an important industry that increases farmers' income, improves agricultural efficiency, promotes regional economic development, and has a large advantage in domestic and foreign markets. However, the flavor substances of fruits and vegetables are important indicators for evaluating the quality of fruits and vegetables, and the types and contents of flavor substances will change greatly during the drying process.

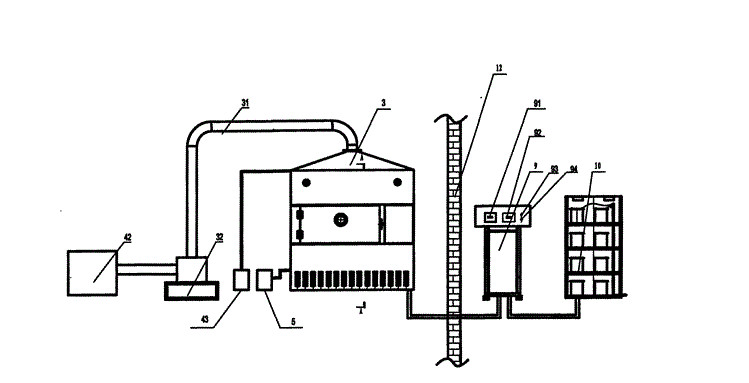

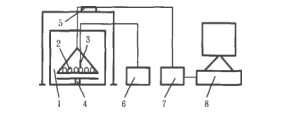

This paper focuses on the current domestic and international research on the effects of hot air drying, vacuum freeze drying, microwave drying equipment and joint drying and other drying techniques on the volatile flavors and non-volatile flavors of fruits and vegetables, as well as the changes in flavor substances caused by different drying techniques. Based on the research progress of the causes of fruit and vegetable drying technology at home and abroad, the current situation and existing problems are analyzed, and the possible development direction of the application of drying technology in flavor materials of fruits and vegetables is proposed. Provide reference for the study of the flavor quality of dried fruits and vegetables.

Key words: microwave drying of fruits and vegetables, volatile flavor substances, non-volatile flavor substances

Drying, as an important way of processing fruits and vegetables, will have a greater impact on the quality of fruits and vegetables, especially on flavor quality. There are many kinds of flavor substances in fruits and vegetables, including volatile flavor substances such as alcohols, aldehydes, esters, acids, alkanes, acids and sulfur compounds, and non-volatile flavor substances such as soluble sugars, organic acids and free amino acids. The former determines the characteristic taste of the food, and provides the precursor substance for the latter synthesis, while the latter is macroscopically expressed as the smell of the food. These substances have extremely small content and different odors, which together form a flavor system of the food.

The unique aroma of fruits and vegetables contributes to the flavor and its content and its threshold value. The unique flavor substances not only can cause people's appetite, but also promote the secretion of digestive juice, so that the body can quickly digest and absorb nutrients, but the characteristic flavor of fruits and vegetables is only This compound is called a "characteristic effect compound", which is determined by fewer components or even a certain compound.

Fruits and vegetables are treated with different drying methods to give different flavors. Drying can significantly increase the content of aldehydes, alcohols, heterocycles and sulfur compounds, and promote the formation of some new compounds, which also lead to cyclic compounds, alcohols, aldehydes, The loss of ketones and the like, the effect of different drying methods on the flavor will vary greatly. The dry quality of the fruit is affected by the level of certain aromatic substances. The food flavor analysis can not only identify the food quality, but also classify and identify the food, which is of great significance to the development of human health and food industry.

This paper mainly describes the effects of hot air drying, vacuum freeze drying, microwave drying and combined drying and other drying techniques on the volatile flavors and non-volatile flavors of fruits and vegetables and the causes of flavor changes caused by different drying techniques. The research progress in this aspect, and discussed the possible development direction of the application of drying technology in flavor materials of fruits and vegetables.