Experimental Study on Microwave Drying Process of Coriander

Abstract: This paper takes coriander as the research object, and adopts microwave drying equipment for single factor test and orthogonal test. In the single factor test, the factors such as material layer thickness, relative microwave degree and microwave temperature are changed respectively. The effect of the change on the drying characteristics and quality of fresh coriander. Through orthogonal test, the optimal process parameters of microwave dried coriander were as follows: material thickness 30 mm, relative vacuum 0.086 MPa, vacuum temperature 80 °C.

Key words: coriander microwave drying; drying curve; comprehensive scoring method

Coriander is also known as medlar. In the history of human consumption, the earliest aromatic vegetables are coriander. Because of its green color and aromatic taste, it plays an important role in delicious food. It is an indispensable seasoning, in the stems and leaves of coriander. Contains abundant elements required by the human body, such as protein, fat, fiber, water, minerals, carbohydrates, vitamin C, vitamin B1, vitamin B2, calcium, phosphorus, sodium, iron, carotene, riboflavin, thiamine, Potassium and oxalic acid; at the same time, coriander also contains a large number of amino acid nutrients. After the body absorbs these substances, it provides nutrients for human growth and development through its own metabolic pathways, and maintains the substances or energy required for life activities.

The drying process of coriander is the basic key process for the deep processing of coriander. At present, the processing method of coriander has low production efficiency, high labor intensity and poor sanitary conditions, which makes the quality of featured products low, which is difficult to be accepted by the domestic and overseas markets, far from catching up with the food industry. Scale, refinement, and automation. Because the seasonality of coriander is very strong, the yield of coriander can not meet the large demand of the market. With the development of society and the improvement of people's quality of life, dry products are more and more favored. Therefore, the vegetables are dehydrated and stored as vegetables. The best way.

At present, for the drying research of coriander, China mainly has several drying methods such as hot air drying, freeze drying and microwave drying, but no vacuum drying of coriander is observed. 90% of them are dried by atmospheric hot air, which has the characteristics of simple operation, large output and low production cost. However, the dehydrated vegetables after hot air drying have low nutrient preservation rate and poor rehydration.

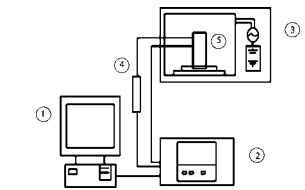

Although microwave drying has many advantages, it often causes local overheating, surface hardening, color irregularity, and uneven heating. In addition, its energy efficiency is not high. However, although the dried product obtained by freeze-drying is of good quality, The investment cost is high; the vacuum drying process is to dry the material in a closed drying chamber by vacuuming and heating, thereby isolating the material and the air, and because the vacuum environment reduces the boiling temperature of the water boiling, Preventing the oxidative deterioration of the dried material, avoiding the browning of the pigment, and the like, so that the processed dry product has better quality.

After rehydration, the characteristics of the raw materials are basically maintained. In addition, the drying cost and equipment cost of vacuum drying are relatively low, and it plays an important role in food drying. In order to obtain the drying characteristics and quality of the coriander, the dehydration test was carried out on the fresh coriander by vacuum drying.