Experimental Study on Microwave Drying Technology in Drying Chinese Medicine Huangqi

Abstract: The applicability of microwave drying technology in the processing and production of Chinese traditional medicine Huangqi was studied. The characteristics of microwave drying technology were summarized, and the optimal treatment method of Huangqi concentrated extract by microwave vacuum drying was explored. Astragalus tablets were used as test samples. The experiments were carried out by dry contrast experiments and microwave drying. The relative density, drying temperature and vacuum value of the extracts were used as variables.

The results show that: the microwave drying time is the shortest, the extract 52. 2%, baicalin (C21 H18 O11) content 10. 2%; optimal vacuum drying conditions for Astragalus concentrated extract: The relative density of the extract is 1. 35, drying temperature is 70 °C, vacuum value - 0. 07 Mpa. Microwave drying equipment is an effective, practical, promising and promising new drying technology suitable for the Chinese medicine production industry with high requirements for drying.

Key words: microwave drying jaundice; traditional Chinese medicine extract

Scutellaria baicalensis Georgi, also known as Camellia sinensis, is a perennial herb of the genus Astragalus. It is root-medicated, bitter, cold, and has the effects of clearing heat and detoxification. It mainly treats cough, upper respiratory tract infection, hemostasis, fetus, dysentery and other diseases. The clinical antibacterial effect of jaundice is better than that of berberine, and it does not produce drug resistance. Modern research has shown that Astragalus mainly contains components such as astragalus and baicalein, and most of them exist in the form of free aglycones or combined oxyglucosides.

Astragalus membranaceus has broad-spectrum antibacterial characteristics and has a good inhibitory effect on a variety of bacteria, fungi, spirochetes, etc. It also has a good bactericidal effect against Staphylococcus aureus which is resistant to antibiotics.

The 2015 edition of the Chinese Pharmacopoeia stipulates that the moisture of dried medicinal herbs should not exceed 12%, and the content of baicalin (C21 H18 O11) should not be less than 9. 0%. Modern Chinese herbal medicine drying technology mostly adopts the principle of hot air drying, and the production cost is low, but the loss of active ingredients is also large, and even there is a serious quality decline phenomenon. With the development and application of new drying technologies and equipment, higher requirements are placed on the improvement of the drying quality of Chinese herbal medicines, the reduction of energy loss and the reliability of operation. Drying will develop in the direction of improving product quality, effectively utilizing energy, reducing environmental impact, using computer to improve self-control, and simple operation.

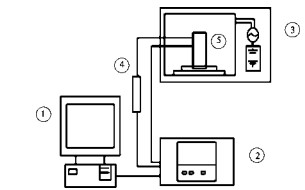

Microwave vacuum drying technology is a new drying technology combined with microwave drying technology and vacuum drying principle. Taking full advantage of the advantages of the two drying technologies, microwave energy provides a heat source for vacuum drying, overcomes the shortcomings of the conventional method of slow heat transfer rate, and can be dried at a lower temperature to avoid charring due to oxidation and heating overheating. , crust formation and hardening occur. It not only preserves the nutrients of the material well, but also shortens the drying time and improves the production efficiency.

In recent years, the application research of microwave vacuum drying technology at home and abroad has mainly focused on the drying of agricultural products such as vegetables and fruits, and research on the production and processing of Chinese herbal medicines is still relatively rare. Li Yuanzhi et al. studied the process of making instant banana powder by clarifying banana juice after enzymatic hydrolysis by microwave vacuum drying equipment. It was found that many indexes of products after microwave vacuum drying were superior to those of hot air drying.

Clary research shows that by controlling the microwave vacuum drying temperature, the production quality of grapes can be effectively improved. Sun Lijuan and other Ganoderma lucidum products dried by microwave vacuum drying technology, the retention rate of Ganoderma lucidum polysaccharide and triterpenic acid is very close to that of freeze-dried products, and is much higher than that of traditional vacuum drying (60 °C ~ 65 °C). The microwave vacuum drying time is much shorter. In this study, the Chinese medicinal material Astragalus membranaceus was used as the test product, and the microwave vacuum drying technology was compared with the commonly used drying technology. The scutellaria extract was used as the test sample, and microwave vacuum drying was used to determine the extraction and concentration of Astragalus membranaceus. The best drying conditions for