Fuzzy Control of Honeysuckle Microwave Drying

Summary: In order to achieve the honeysuckle microwave drying equipment the parameter control proposes to apply the fuzzy control strategy to the intelligent control of the microwave dryer to realize the decoupling and precise control between the temperature and humidity of the drying process. The fuzzy logic toolbox of MATLAB is used to design the fuzzy controller with two inputs and two outputs, and the control system is simulated by SIMULINK in MATLAB. The simulation results show that the control process is smooth and the control effect is ideal after applying fuzzy control. It is verified by experiments that the intelligent control system has stable operation, reliable performance and high control precision, which ensures the drying quality and reduces the drying energy consumption. The moisture content of the material after drying is very close to the ideal value, realizing the automation of the microwave continuous dryer. Intelligent.

Keywords: Honeysuckle microwave drying; control system; fuzzy control; temperature and humidity

Honeysuckle is a honeysuckle plant with sweet and cold taste. It has the functions of clearing away heat and detoxifying and evacuating wind and heat. It is used for carbuncle, throat, erysipelas, heat and blood stasis. Its main active ingredients are organic acids and flavonoids. Modern pharmacological studies have shown that honeysuckle has antibacterial, antiviral, anti-inflammatory and antipyretic effects, anti-oxidation, hypolipidemic and hypoglycemic effects. The consumption of honeysuckle in the fields of medicine, health care, food and other fields has increased year by year, and the market is in short supply. However, honeysuckle will produce mildew during the drying process. Mildew will affect the dry quality of honeysuckle, such as sensory and chlorogenic acid content, so the drying process is very important.

At present, the microwave drying process of honeysuckle has been relatively mature. In the process of microwave drying of honeysuckle, temperature and humidity have an important influence on drying time and final quality. In the development process of honeysuckle drying equipment, how to realize the control of temperature and humidity is an important means to control the quality of honeysuckle drying.

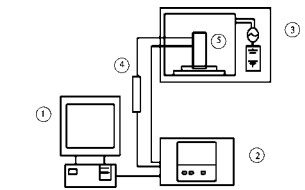

The process parameters control of microwave continuous drying of honeysuckle mainly include: the temperature of honeysuckle in the drying chamber, the humidity in the drying chamber and the moisture content of the export honeysuckle. The temperature control mainly controls the output power of the microwave magnetron distributed in each drying chamber. If the temperature is high, the output power of the magnetron is lowered, and vice versa. The humidity control mainly controls the rotation speed of the exhausting fan above each drying chamber. If the humidity in the drying chamber is large, the rotation speed of the moisture exhausting fan is increased, and vice versa. The moisture content control of the export honeysuckle is mainly to control the belt speed of the conveyor belt during the whole drying process. If the water content of the export honeysuckle is higher than the ideal value, the belt speed of the conveyor belt is lowered, and vice versa.

In general, there are many control factors involved in the continuous drying of honeysuckle in microwave, and these parameters interact with each other, especially the temperature and humidity in the drying process. The whole drying process is a nonlinear and time-varying. , parameter coupling and complex processes with large lags. Therefore, it is difficult to establish a precise mathematical model of the drying process, and it is difficult to achieve precise control of the drying process.

Regarding the control of the drying process, many scholars at home and abroad have carried out a lot of research. Liu et al. designed a dryer model predictive controller, which can control the moisture content of the exported materials to ±0.7%; the researchers will separately control the fuzzy control. The PID control is applied to the fluidized bed drying test. The results show that the control characteristics of the fuzzy control are better than the PID control, and the structure of the fuzzy controller is simpler than that of the PID controller.

Thyagarajan et al. applied intelligent control to dry food. However, in the existing research, the control object can establish an accurate mathematical model, and the control target is single, the control parameters are few, and there is no coupling between the parameters. In view of this situation, this experiment proposes to adopt fuzzy control technology in the control of the ring microwave continuous dryer. Automated control of the honeysuckle drying process.