Optimization of Microwave Drying Process for Tungsten Concentrate

Abstract: Tungsten concentrate microwave drying equipment is an important process in the processing of tungsten ore. The steam oven drying process originally used in the persimmon garden multi-metal plant has problems such as long drying time, uneven drying of tungsten concentrate, high energy consumption, low efficiency, serious environmental pollution, and high labor intensity. The key technical parameters of microwave drying black tungsten concentrate were optimized by the combination of simulation and test methods.

The industrial test results show that under the condition of optimizing the process parameters, the relative dehydration rate of the black tungsten concentrate reaches over 90%, which can meet the industrial production requirements. Compared with the original black tungsten concentrate steam drying system, the drying efficiency is improved by 50%, the product dryness is increased by 60%, the heat energy utilization rate is increased by 50%, and the production automation is high.

Key words: black tungsten concentrate microwave drying; process flow; parameter optimization

The tungsten concentrate drying process is an important process in the processing of mineral concentrate processing and production, and is also an important link that restricts product quality and output.

The drying of tungsten concentrate in a polymetallic plant of Hunan Shizhuyuan uses steam oven drying process, which has the disadvantages of high energy consumption, low efficiency, long drying time and serious environmental pollution. The microwave drying method for tungsten concentrate is proposed. And for the key technologies such as parameters in the process and process design, the combination of theoretical analysis and industrial simulation test is used to carry out related research work.

In the actual production situation, because the moisture in the material preferentially absorbs a large amount of microwave energy, a high vapor pressure is formed in a short time, so that the moisture in the material quickly escapes the surface of the material. Reduces overall heating of the material and reduces energy consumption. Because of its unique drying method, it has the advantages of short drying time, fast drying speed, high heat energy utilization, high product dryness and easy production control, which makes the technology better adapt to the production needs of modern mineral concentrate drying. Effectively improve the traditional drying methods and reduce the shortcomings of environmental pollution.

The essence of microwave drying is to directly interact the microwave with the product to be dried, convert the electromagnetic energy into heat energy instantaneously, and use the loss of the medium to realize the process of rapid dehydration and drying of the dried product. Because the loss factor of water molecules in the material can greatly convert the microwave energy into heat energy, the microwave heating heat is generated inside the material to be heated, so that the heat inside and outside is not only uniform temperature, but also the internal temperature is higher than the external temperature gradient direction and moisture. The direction of the gradient is the same. The heat transfer and mass transfer directions are the same, which promotes the rapid evaporation of water inside the material.

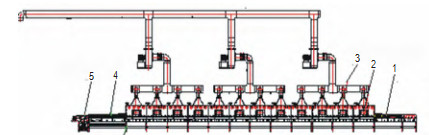

The formation of an internal pressure gradient allows the moisture to diffuse rapidly to the surface, making the drying time much shorter. The microwave directly converts electromagnetic energy into thermal energy through direct interaction with the product, realizing the process of rapid dehydration and drying of the product. The microwave drying equipment mainly consists of the inlet and outlet end suppression chamber, the microwave drying furnace chamber, the exhaust system, the transmission device, the electronic control system, the waterway system, and the microwave magnetron.

Microwave heating is to generate an alternating external electric field that is identical to the above principle by a microwave magnetron, and is rapidly heated by the interaction of the microwave field with the medium molecules.