Research on drying technology of wood and wood products

Abstract: This paper briefly describes the development of drying technology for wood and wood products. It briefly introduces the principles and development status of various drying technologies, finds out the lack of wood drying technology, and creatively proposes atmospheric freezing in low temperature environment. Drying technology, and introduced the principle and classification of atmospheric pressure freeze-drying technology, opened up a new idea for wood drying technology in the low temperature direction.

Keywords: microwave drying equipment; low temperature; atmospheric pressure; freezing

Drying is an indispensable part of the processing of wood products. Wood drying refers to the process of using the difference between the internal and external water vapor pressures in the heating process to reduce the internal moisture content of the wood to within the specified numerical range. This process plays an important role in the field of wood processing and its manufacture, and is one of the most technologically advanced processes. If the wood and its wood products are not properly treated in the drying process, it will cause cracking, discoloration, etc., and the quality will be problematic, so that the wood and its wood products cannot be used and will be wasted.

China is a big country in the production of wood products, so the demand and consumption of wood is huge. According to statistics, from January to September 2013, China imported 51.846 million m3 of logs, sawn timber, sheet metal and sleepers from abroad, up 15.86% over the same period of 2012. And the import volume keeps rising.

These imported woods are artificially dried for production and life, but only 20% of imported wood is artificially dried. The main reason is that rapid drying is not possible. At present, wood drying is mainly based on conventional drying methods. Most of the common wood products are made of precious materials such as mahogany and logs, and the wood used is large in size. It is difficult to meet high-quality wood products using conventional drying methods. Drying requirements. In recent years, research on new, efficient, energy-saving and safe drying methods has become a research hotspot of scholars all over the world.

The most energy-intensive process in the processing of wood products is wood drying, which accounts for 40% to 70% of the total energy consumption of wood products. Drying technology plays an important role in the field of wood processing and manufacturing. Many experts currently Committed to the research of wood drying technology. Conventional drying, microwave drying, dehumidifying drying, vacuum drying, solar drying and the like are common methods for wood drying, and some combined methods are used in actual production, such as conventional steam-dehumidification combined drying, solar heat pump combined drying, and the like.

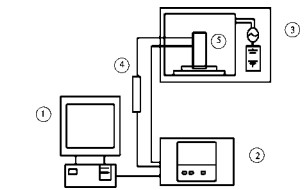

Microwave drying of wood is to place wet wood in a microwave alternating electromagnetic field. Under the action of frequent alternating electromagnetic fields, the polarized molecules in the wood rapidly rotate, rub each other and generate heat, thereby heating and drying the wood. Zhang Wenhui conducted a comparison test on microwave drying of thick wood, and concluded that the temperature gradient from the inside to the outside is formed in the rising speed section under different microwave power; the thicker wood above 50 mm, the higher the water content, the better the ventilation, the temperature gradient is formed. The faster and more stable.

Li Xianjun et al. believe that the difference in dielectric properties of wet wood, the uneven distribution of microwave field strength and the unreasonable process control will lead to quality defects such as cracking and carbonization after drying. Liu Zhijun's research on microwave drying of Pinus massoniana wood shows that the microwave drying process is divided into three stages, the acceleration section, the constant velocity section and the deceleration section. The equal velocity section accounts for the largest proportion, and the initial temperature rise and isothermal temperature rise phases are relatively stable. The temperature difference in the stage increases.