Research Status and Prospects of Tea Drying Technology

Abstract: Drying is an important process in the initial processing of tea, which is of great significance for the formation of sensory quality of tea. During the drying process, under the action of heat and force, with the continuous loss of moisture, the physical properties and endoplasmic components of the product change drastically, thus forming the unique sensory quality of the tea.

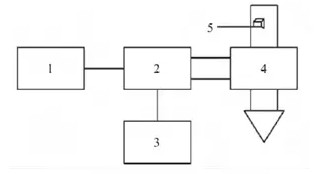

The author expounds the principles and characteristics of the drying technology of Chinese tea, and points out the trend of tea drying from single technology to joint application technology, and proposes to improve the basic research of new joint drying technology and the on-line detection technology of dry product moisture. The development of new tea microwave drying equipment and future tea drying technology provide certain development ideas.

Key words: microwave drying of tea; drying principle; single drying; combined drying; on-line detection

Drying is a key process in the initial production of tea, which forms different sensory qualities of tea while removing excess water. In recent years, with the increase of consumers' health awareness, tea processing technology has developed towards green, low-energy and energy-saving. The use of traditional energy processing such as coal and wood has been unable to meet the development requirements of clean, standardized, continuous and even intelligent tea.

Therefore, on the premise of ensuring the maximum retention of active ingredients and developing sensory quality of tea, on the basis of traditional drying techniques and principles, scholars try to learn from the advanced drying techniques of other agricultural products such as fruits and vegetables, food, etc., aiming to explore the optimal effect of tea processing and drying.

Here, the author reviews the research status of tea processing and drying technology, and points out the shortcomings and development direction of the existing research, aiming at promoting the development of tea processing and drying technology, improving the quality of tea products, and drying tea technology and equipment in the future. The research and development provides a reference.

At present, the application of single drying technology in the field of tea has been widely studied and applied, but the new joint drying technology is still in its infancy, and only a few studies are only in the stage of component research and some equipment parameters exploration. The research system of the system, especially the drying mechanism, is still in a blank state.

Taking vacuum freeze-drying as an example, due to the difference in the material grade of the tea and the mechanical composition of the same raw material, the water content of the stem, bud and leaf of the tea is not the same. Therefore, it is necessary to determine the proper pre-freezing temperature of the material before vacuum freeze-drying, and the pre-freezing of the material. The freezing temperature and sublimation temperature can only be accurately set when the eutectic point, the inflection point and the glass transition temperature are determined. This is a key control point for controlling the quality stability of dry products, which not only can control the end of the freezing process more accurately. In addition, the energy consumption can be greatly reduced to shorten the freeze-drying cycle. Therefore, similarly, the drying method needs to improve the detection of the material eutectic point, the inflection point and the glass transition temperature, so as to achieve the purpose of optimizing the quality and saving energy.

In addition, some new dry technologies such as high-pressure pulsed electric field (HPEF) combined with vacuum freeze-drying technology, microwave combined vacuum freeze-drying technology, and radio-hot air combined drying technology have been widely studied in the food industry . It also provides a potential research direction for the new drying technology of tea.