Advances in Rice Drying Technology and Quality Evaluation

This paper summarized the achievements of rice drying technology and technology, rice drying quality research, and discussed the relationship between drying technology and rice drying quality, in order to provide reference for the research of rice microwave drying equipment.

Key words: rice microwave drying; quality

The rice should be dried in time after harvest, otherwise it will have an important impact on the subsequent rice production, processing and preservation. According to the estimates of relevant departments, more than 5 million tons of cereals are lost every year because they cannot be dried in time. Therefore, timely drying and precipitation of rice is of great significance to rice production and processing.

Drying technology is an indispensable technology in modern industrial and agricultural production. The drying effect will directly affect the quality and shape of products. Drying technology includes complex mechanism of mass transfer and heat transfer, which involves a wide range of disciplines and is closely related to the characteristics of drying materials.

At present, with the improvement of living standards, people pay more and more attention to the quality of rice, which forces people to improve drying technology and drying technology. How to measure the quality of dried rice varies. Many researchers have tried various evaluation methods and studied the factors affecting the quality of dry rice.

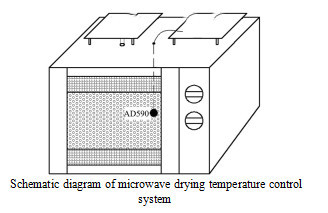

Microwaves with frequencies of 915 and 2 450 MHz are often used for rice drying. Microwave can be absorbed directly by paddy without intermediate medium, causing rapid collision of internal molecules, friction and heat generation, and uniform overall heating, forming temperature and humidity gradient in the same direction, promoting the evaporation of internal moisture, so as to achieve the purpose of drying.

Based on the research of microwave and glass transition, Xu Fengying et al. proposed that in order to improve the quality of rice, low power microwave retarding sulfur drying process could be used in the late drying stage to obtain better drying effect. Yang Huiping and others have found that low temperature microwave drying can reduce the impact of temperature fluctuation on the quality of rice, while high temperature microwave can easily damage the quality of rice, which is not conducive to later storage and consumption.

Microwave drying of paddy has high efficiency and no pollution. It can also improve the processing and eating quality of paddy, and help to improve the economic benefits of paddy. However, Wang Suya and other experiments show that microwave drying is more likely to cause burst waist of Indica rice, which is not suitable for drying indica rice. Therefore, the microwave drying technology is still needed to be further studied in the aspects of rice varieties suitable for drying and rational utilization.

The correlation between drying technology and quality index is different. Different drying technology can also affect the quality index parameters of different paddy. Relevant studies have shown that the accumulation rate of total fatty acids in microwave-dried rice during storage is significantly slower than that in hot air drying, and the higher the power, the lower the fatty acid value after storage. Therefore, this technology is more conducive to long-term storage of rice.

For example, vacuum drying can significantly reduce the bursting waist and expansion of paddy, which is suitable for the drying process of heat-sensitive (heat-sensitive, easily decomposed) materials. However, at higher vacuum (greater than 0.06 MPa) or temperature, the fatty acid value of rice will gradually increase, which will ultimately affect the quality and storage resistance of rice. In addition, a large number of studies have confirmed that different drying technologies and drying parameters will have a great impact on the comprehensive quality of rice.

For example, the change of drying parameters, the setting of constant and variable temperature, high temperature and low temperature, and the setting of soot-softening time will make the grain quality indexes such as bursting waist rate, roughness, gelatinization characteristics, amylose content and fatty acid value change obviously. However, in China, the correlation between drying technology and quality indicators is insufficient, which still needs further study and discussion.