Study on the influence of production process and drying method on the quality of instant rice porridge

Abstract: The production process of instant rice porridge was explored. The optimal process parameters were determined by orthogonal experiment, and the microwave drying equipment was compared and analyzed.

The results showed that the ratio of monoglyceride to β-cyclodextrin was 3 g / kg: 5 g / kg, the soaking temperature was 55 °C, the soaking time was 40 min, and the cooking time was 10 min. Good production parameters; Freeze-assisted hot air - Microwave drying method is the best drying method for preparing instant rice porridge, specifically: first freeze at -20 °C for 20 h, then at 80 °C for 40 min, then use 240 W microwave treatment for 5 min. This method can significantly improve the rehydration, the rehydration time is 6.5 min, and the sensory quality of the product is optimal.

Key words: millet microwave drying, instant porridge, frozen auxiliary hot air - microwave drying, rehydration, sensory quality

Xiaomi is China's traditional food crop, the first of the “grain”, and has a history of more than 7,300 years of cultivation. Millet has rich nutritional value, and the content and quality of dietary fiber, mineral elements and polyphenols are among the highest in the grain.

Except for the low lysine content, other amino acid ratios are basically in line with the ideal model proposed by the WTO. At the same time, millet protein is a hypoallergenic protein, which is especially suitable for pregnant women, infants and children. Foreign studies have shown that millet polyphenols have strong antioxidant activity, and have physiological effects such as lowering blood sugar, lowering cholesterol and preventing ulcers.

With the continuous development and deepening of millet deep processing products, high-nutrition foods developed with millet as raw materials have become more and more popular. They are mainly suitable for infants, the elderly, patients, etc., and can also be used as breakfast foods, beauty foods and special foods. .

Convenient instant porridge is a kind of convenient food that has gradually emerged in China's food industry in the late 1980s and early 1990s. It is a fast food product processed by modern grain processing physical modification technology.

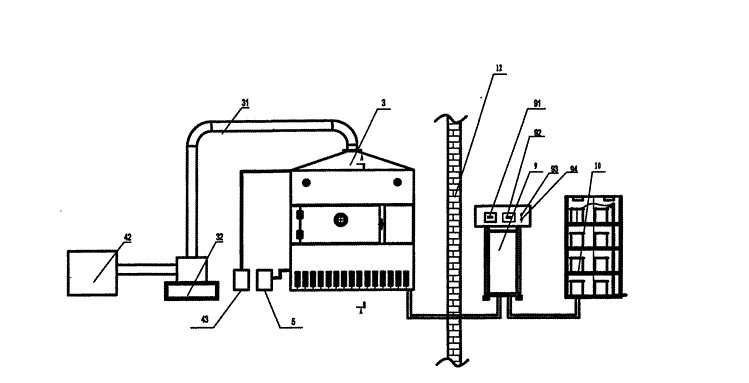

At present, domestic scholars have made some achievements in the research on the production process of instant porridge. Baiyunjing and other methods have improved the rehydration and stability of rice porridge by adding β-cyclodextrin. However, the sensory quality has not been studied in depth. Zhang Min et al. used microwave-vacuum drying method, Huanghua and other secondary cooking methods. Wang Lidong and others used microwave-hot air drying method to make instant porridge, but the cost of vacuum equipment was high, and microwave hot air method failed to achieve a good uniform effect on product appearance and rehydration, while secondary cooking was beneficial to industrial production, but The product rate is low.

In this experiment, the effects of additives on the production process, sensory quality and rehydration of the products were studied, and the optimal process parameters were obtained. Through the research of drying methods, the preparation of millet instant porridge was proposed by the freeze-assisted hot air-microwave drying method. In order to provide reference for the further research and development of Xiaomi convenience food.