Effects of Different Pretreatments on Drying Quality of Sweet Corn Kernel

Sweet corn, also known as vegetable corn, belongs to Gramineae and Corn. It is a sweet subspecies of corn and one of the main vegetables in developed countries such as Europe, America, Korea and Japan. It contains a variety of essential human proteins, carbohydrates, amino acids and vitamins, coupled with its sweet, tender, fragrant characteristics and is favored by consumers of all walks of life.

Sweet corn dry product is a new type of fruit and vegetable food, which has been developed rapidly all over the world.

Pretreatment is an important process in food processing, and many processed products need this unit operation. Generally speaking, pretreatment plays an important role in maintaining the color, aroma, taste, shape and nutrition of the final product. Scholars at home and abroad have done a lot of research on the pretreatment of fruit and vegetable processing. The author studied the microwave drying of sweet corn by two pretreatment methods: blanching and microwave drying equipment.

The influence of quality is expected to provide some theoretical guidance for practical application.

1.1 materials and reagents

Quick-frozen fresh corn kernels: purchased in Huarun supermarket, stored in ultra-low temperature refrigerator, initial moisture is about 76.8%.

1.2 instruments and equipment

GZX-GF101-2BS Electric Heating Blower Dryer: Shanghai Yuejin Medical Device Factory; PB203-N Electronic Balance: Metler-Toledo

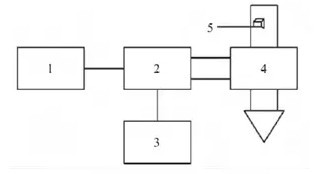

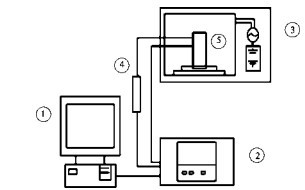

(Shanghai) Instrument Co., Ltd; CR-400 Chromatometer: Konica Minolta (Investment) Co., Ltd; MVD-1 Food Drying Testing Machine: Shangyu Xinye Instrument Machinery Co., Ltd; HH-S Digital Display Constant Temperature Oil Bath Pot: Jintan Jingda Instrument Manufacturing Factory; A11 Basic Grinding Machine: Guangzhou Instrument Laboratory Technology Co., Ltd. Physical property analyzer: TA. XT Plus, Stable Micro System, UK; YHW2S-OS vacuum microwave freeze dryer: Nanjing Yatai Microwave Energy Technology Research Institute.

1.3 experimental method

1.3.1 The pretreatment method was untreated (control), hot water blanching (80 C blanching for 3 minutes), and 3% brine immersion for 12 hours.

1.3.2 Vacuum microwave drying, vacuum freeze drying and high vacuum drying were used to dry the pretreated sweet corn kernels until the moisture content was about 5%. Vacuum microwave drying: vacuum 7 KPa, microwave power about 8 W/g; high vacuum drying: vacuum 100 Pa, power 500 W, temperature 50 C. Vacuum freeze-drying: vacuum 100 Pa, power 500 W, temperature 50 C.

1.3.3 Hardness and brittleness are measured by physical property analyzer. The test conditions are as follows: probe P25; operation mode: pre-test speed 5 mm/s; test speed 2 mm/s; post-test return speed 2 mm/s; deformation amount.

30%, induction force 5 g, downward pressure distance 5 mm. The hardness value/g is equal to the peak value of the force in the curve, i.e. the maximum force required for sample fracture. The larger the value, the harder the product is. The brittleness value/g is expressed by the first obvious peak pressure on the coordinate chart during the first impulse of the downward pressure probe to the sample. The smaller the value, the better the brittleness of the product [7]. Repeat each sample five times and take its average value.

1.3.4 Colorimetry In order to determine the color of corn kernels more accurately, the color difference of corn kernels was determined by color difference meter after beating them.

conclusion

1) Compared with untreated, blanching and brine impregnation pretreatment could improve the quality of sweet corn kernels under three drying conditions, and the most important one was high vacuum drying. Compared with the two pretreatments, the quality of sweet corn kernels pretreated by brine impregnation was better than that pretreated by blanching, but the drying time was prolonged.

2) Among the three drying methods, salt water impregnation pretreatment of high vacuum drying sweet corn grains is yellowish, smooth skin, complete skeleton structure, uniform expansion, loose internal structure, crisp taste, moderate hardness, while vacuum freeze drying, low brittleness, slightly inferior to high vacuum drying, but not processed vacuum freeze-drying products. It is similar to high vacuum drying with brine impregnation pretreatment. Considering the quality and production cost, high vacuum drying is undoubtedly the best choice.