Study on Preparation of rehydrated mung bean sprouts by microwave drying

Absrtact: Mung bean sprouts were pretreated by blanching, crispness preservation and sucrose immersion, then dried by microwave, and processed into dehydrated vegetable products.

The optimum conditions of microwave drying equipment are microwave power 300 W, loading 120 g and paving thickness 4 mm. The maximum rehydration ratio of dry products is 4.35. The content of nutrients in rehydrated mung bean sprouts was higher than that in fresh mung bean sprouts, of which protein was 2.46%, crude fiber was 0.92%.

Key words: microwave drying mung bean sprouts; rehydration

Bean sprouts, rich in dietary fiber, VC and other bioactive ingredients, are a popular popular vegetable with certain processing and utilization value. On the other hand, because of the poor storage and fragility of fresh bean sprouts, they can not be transported over long distances, resulting in small sales radius, poor market adjustability and serious corruption and waste. Mung bean sprouts have the functions of invigorating the spleen and appetizing the stomach, digesting and accumulating, clearing away heat and detoxifying, which are more popular than other bean sprouts such as soybean sprouts.

The purpose of this experiment is to process mung bean sprouts into dehydrated products with a certain shelf life, nutrition and convenience for eating with fresh mung bean sprouts as raw materials. Change the current situation of single consumption form of mung bean sprouts market, and then expand its consumer population and sales market, improve the commodity value of mung bean sprouts.

In 0.15% citric acid solution, the peroxidase activity of buds was completely inactivated after blanching for 2.5 minutes at 90 C. The content of hexaaldehyde was very low. The presence of beany odor was almost not detected in sensory evaluation. At the same time, the comprehensive score of color, odor and brittleness was higher.

After immersing in 0.4% calcium chloride solution for 60 minutes, the blanching buds can be restored to a certain degree of brittleness. After blanching in citric acid solution, pectin decomposes and becomes soft and translucent. Calcium chloride has a certain effect on the recovery of bud brittleness, but there is still a certain gap between fresh buds. After washing, the rehydration of buds could be effectively improved by immersing them in 15% sucrose solution for 30 minutes.

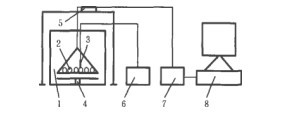

Under different microwave power, the drying rate curves of mung bean sprouts differ greatly, followed by loading and paving thickness, in which paving thickness has little effect.

The optimum conditions for microwave drying of mung bean sprouts are microwave power 300 W, loading 120 g and paving thickness 4 mm. The maximum rehydration ratio of dried products is 4.35.

The content of nutrients in rehydrated mung bean sprouts was higher than that in fresh mung bean sprouts, of which protein was 2.46%, crude fiber was 0.92%.