Research Progress of Oolong Tea Drying Technology

Absrtact: Although the drying process is the last process of tea processing, it plays an important role in the formation and fixation of tea quality.

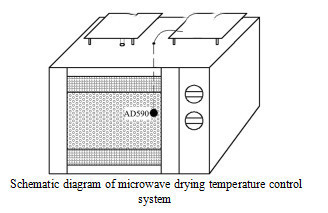

At present, some new drying technologies suitable for tea industry have been slowly used in tea industry, including microwave drying equipment, infrared drying, far-infrared drying, vacuum freeze-drying, vacuum low-temperature drying and so on. It is helpful for the formation of high quality tea products to explore the drying technology suitable for the development of tea industry in China.

Key words: drying technology; tea microwave drying; physical and chemical components

Oolong tea is one of the six most complex types of tea. Because it is semi-fermented tea, and the degree of fermentation can be controlled according to the need to make products in line with market demand. Oolong tea processing process is more complex, including: withering, green, kneading (wrapping), drying and other processes.

In these processes, the green-making process is the most critical, of course, other processes also play an indispensable role in the formation of high-quality wool tea. As the last process, the drying process directly affects the color, aroma and shape of the tea. Therefore, how to do a good drying process will play a vital role in the quality of wool tea.

The main purpose of drying process is to lose water in tea after rolling (or wrapping) in order to facilitate the formation and storage of tea. Proper drying treatment can also improve the quality of tea, so that the sensory quality and content of tea can be upgraded to a level.

According to Miao Aiqing's research, drying process can increase the contents of linalool and its oxides, geraniol, methyl salicylate and alpha-terpene alcohol in tea, which are all part of the aroma components of Oolong tea. The elevation of these components plays an important role in improving the quality of Oolong tea.

In the traditional drying process, the content of polyphenols in Oolong tea will not change significantly. Amino acids, soluble proteins and soluble sugars, to a certain extent, will decrease slightly due to the influence of heat treatment.

With the rapid development of science and technology, more and more drying technologies will be applied. Vacuum freeze drying technology combined with hot air drying and microwave drying. At present, China's tea industry needs safe, efficient, clean and continuous technology and equipment, which will be conducive to the better development of China's tea industry.