Effect of drying technology on the quality of Cigu mushroom crisps

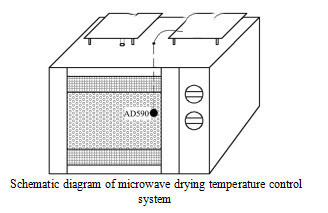

ABSTRACT: The effects of four different drying methods, hot air drying, microwave drying equipment, vacuum microwave drying and hot air-microwave drying, on the physical properties, nutrient composition and microstructure of Cigu chips were studied.

The results showed that hot air drying had little effect on the color of Cigu chips, but its hardness and brittleness were poor; microwave drying and vacuum microwave drying had moderate hardness and brittleness, but poor color and flavor; hot air-microwave drying had the best color, moderate hardness and brittleness, the best sensory quality and the higher polyphenol retention rate; hot air-microwave drying had better effect on the color and brittleness of Cigu chips. The good swelling effect may be related to the formation of more uniform porous structure.

Key words: Cigu microwave drying; drying method; quality

Cigu is a perennial perennial perennial shallow-water herb of Alismatidae. It is planted in all parts of China. But it mainly distributes in the Yangtze River Basin and its south region. It provides one of the main aquatic vegetables for winter and spring vegetables in the off-season. Cigu is rich in starch, protein, sugar, inorganic salts, VB, VC and trypsin and other nutrients.

It can replace rice and wheat to become special cereals and is easy to digest. Studies have shown that it also has anti-cancer, anti-oxidation and anti-liver fibrosis effects. As a natural food resource, its nutritional and health value has attracted people's attention.

As the main product of fruit and vegetable processing, fruit and vegetable dried products have developed rapidly in recent years, and the demand at home and abroad has increased greatly. Through drying, the moisture content of materials can be reduced to a certain extent, the shelf life of food can be prolonged, and the cost of storage and transportation can be reduced. However, the physical and chemical changes of materials in the drying process will directly affect the quality of final products.

Therefore, the research on the quality of drying products has become a hot topic in recent years. At present, the main methods of fruit and vegetable drying are hot air drying, microwave drying, low-temperature frying drying, vacuum freeze-drying and so on.

In this experiment, Cigu was used as raw material to compare the effects of four common drying methods: hot air drying, microwave drying, vacuum microwave drying and hot air-microwave drying on the quality of Cigu crisp chips. The purpose was to determine the suitable drying technology for Cigu crisp chips production, and to provide theoretical basis and technical support for the screening, development and application of drying Cigu crisp chips.