Effect of Microwave Drying Technology on Quality Control of Funing Pills

ABSTRACT: Objective To investigate the effect of microwave drying equipment and traditional drying method on the quality control of Funing Pills. METHODS Microwave drying and traditional drying methods were used to compare the effects of Funing Pills made in our hospital. The quality control indexes were used to evaluate the effect of drying.

Result Compared with traditional drying, the total number of bacteria in Funing Pills was significantly reduced, and there was a significant difference between microwave drying and traditional drying. No fungi were detected. The other quality indexes of the finished product of Funing pill all conform to the standard. Conclusion Microwave drying sterilization method is superior to traditional drying sterilization method. It has the characteristics of uniform heating, short drying time, simultaneous drying and sterilization, and stable quality of finished products. It can be widely used in the production of traditional Chinese medicine pills.

Key words: microwave drying Funing pills; paeoniflorin

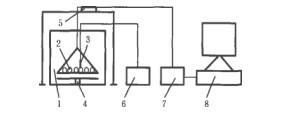

Microwave is an ultra-high frequency electromagnetic wave with a wavelength of 1 mm~lm and a frequency of 300 MHz~300 GHz. The principle of microwave drying is to make use of the high frequency transformation of magnetic field direction to make polar molecules move and friction, thus generating heat. Unlike traditional drying, microwave drying makes the object itself become a heating body.

At present, microwave drying is more and more widely used in the field of traditional Chinese medicine. It has many advantages, such as uniform product, good quality, fast speed, wide applicability, low temperature operation, safety, reliability, high efficiency and energy saving, easy to realize automation, continuous operation and so on.

Funing Pill is a concentrated water pill developed by our hospital for the treatment of premenstrual tension, chronic adnexitis, chest pain, breast disease, dysmenorrhea, menstrual headache and other diseases. It is composed of 15 traditional Chinese medicines, such as Paeonia lactiflora, Bupleurum, Fructus Aurantii, Angelica sinensis, Xiangfu, Peony Bark and Achyranthes bidentata. It has the effect of nourishing blood, regulating liver, removing blood stasis and dredging collaterals.

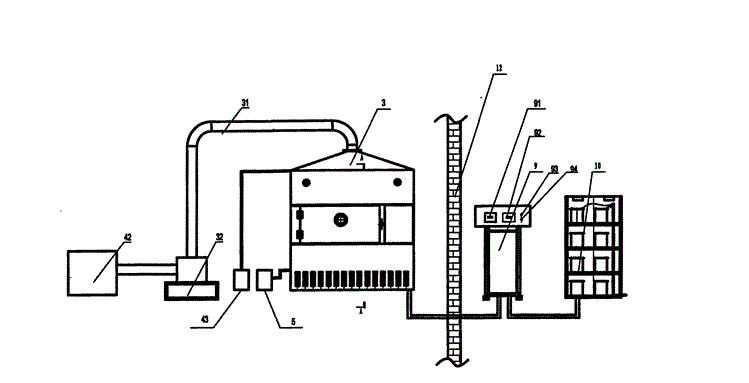

The original preparation process standard is traditional drying. Because the traditional drying process is time-consuming, inefficient and low productivity, our hospital has introduced microwave drying equipment for preparation production in recent years. In this paper, Funing Pill was selected as the research object, and the effect difference between microwave drying sterilization method and traditional drying sterilization method was compared.

Five batches of Funing pills were produced by microwave drying technology. The results showed that all the inspections specified in the quality standard of Funing pills met the requirements. Microwave drying had no effect on the quality of the products. The quality of the finished products was stable and reliable. The microwave drying time was short, the drying speed was fast and the energy utilization rate was high.

Compared with traditional oven drying, microwave drying can control the microorganisms of Funing pills better. After sterilization by microwave drying, the total number of bacteria decreased significantly, and there was a significant difference between them. No fungi were detected. It showed that microwave drying sterilization method was superior to traditional drying sterilization method. This method was used in the production of traditional Chinese medicine pills. The effect of drying sterilization was good, the sterilization time was short, drying and sterilization could be carried out simultaneously without affecting the quality of finished products.

In summary, microwave drying is superior to traditional drying sterilization. It has the advantages of short time, low energy consumption, simultaneous drying and sterilization, and does not affect the quality of finished products. It can realize continuous and automatic production. Because of its high production efficiency and cost saving, microwave drying has gradually replaced traditional drying in hospital preparation production process.