Study on Microwave Drying Characteristics and Kinetics Model of White Fruit

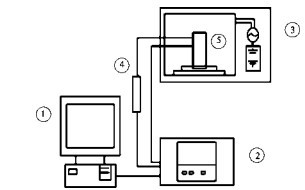

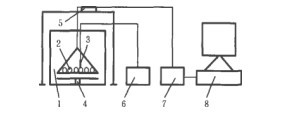

Absrtact: Microwave drying equipment was used to determine the effects of microwave power and loading capacity on drying characteristics of white fruits by single factor experiments with dry-base moisture content, dry-base water loss rate and sensory score as indicators.

The results showed that the dynamic model of water ratio and drying time of microwave drying of white fruits was established by using MATLAB software. The regression fitting test results showed that the drying process of white fruits accorded with Page model, and the correlation coefficient of the model was 0.999. The equation can be used to describe the drying rate at different stages.

Key words: white fruit microwave drying, microwave power density, drying characteristics, kinetic model

Ginkgo biloba belongs to gymnosperm of Ginkgo family. Ginkgo biloba stone, commonly known as white fruit, accounts for 70% of the world's production in China. White fruit is rich in flavonoids, protein and other nutrients, with anti-allergic, antioxidant and other characteristics, widely used in the field of food and medicine. Drying plays a decisive role in the preservation of white fruits, which is a key link in the processing of white fruits, but also a weak link. At present, the traditional hot air drying is mainly used in the drying of white fruits, which is heated from outside to inside.

The shell of white fruit is hard and heat is not easily transferred from the outside to the kernel. Therefore, hot air drying of white fruit is inefficient, energy consumption is high, and it is difficult to ensure product quality. Zhang Caihong et al. Used spray drying to study the drying of Ginkgo and ginkgo pulp. It was found that the instant high temperature of spray drying could lead to the loss of nutrient components and the high cost of energy, and the preparation of Ginkgo pulp was relatively complicated. White fruit drying has become a bottleneck in the development of white fruit industry. Therefore, it is necessary to apply advanced drying methods to the processing of white fruits.

Microwave heating has the characteristics of direct heating, selective heating and mixed heating. Its heating speed is fast and energy consumption is low. It can improve the drying efficiency and product quality of white fruits, and has a certain sterilization effect. It can effectively prolong the shelf life of products, and is more conducive to mechanized and automated production of white fruits.

In this paper, the law of dry-base moisture content and dry-base water loss rate changing with time and the effect of microwave drying on the sensory quality of white fruits were studied when the microwave power and load acted together. The effect of microwave power on drying rate was reasonably controlled under the condition of unit mass of materials. A microwave drying kinetic model of white fruits was established, and regression fitting was carried out to improve the drying efficiency and improve the drying quality of white fruits. To provide theoretical basis and technical support for drying process and product quality optimization.