Microwave drying characteristics of grass carp fillets

ABSTRACT: In order to improve the deep processing and drying technology of grass carp and other freshwater fish, the microwave drying equipment and hot air drying characteristics of grass carp fillets were studied, and the best drying model was determined.

The results show that when the microwave power increases from 200 W to 800 W, the effective water diffusion coefficient increases from 0.995 4*10-9 m2/s to 2.344 3*10-9 m2/s, and when the hot air drying temperature rises from 60 C to 80 C, the effective water diffusion coefficient increases from 4.001 4*10-10 m2/s to 7.291*10-10 m2/s, but the value is still lower than that of microwave drying. Diffusion coefficient value. By comparing correlation coefficient R2, residue square sum RSS and chi square 2, Page model has the highest fitting degree for microwave drying of grass carp fillets, and Two Term model has the highest fitting degree for hot air drying of grass carp fillets.

Key words: grass carp microwave drying; hot air drying; dynamic model

Freshwater fish are abundant in China. Low-value freshwater fish such as grass carp, bighead carp and silver carp account for 60% of freshwater fish production. Fresh fish has more than 80% water content. Microorganisms are easy to reproduce, and their biochemical reactions are more than meat. Therefore, they are easy to spoil and deteriorate, and are not easy to store, which limits the consumption of freshwater fish. Grass carp is one of the most important freshwater economic fishes in China, which is easy to breed.

Grass carp has a simple diet, a wide range of sources of food, a large size, tender meat, rich in protein, amino acids and other nutrients, and fast growth, high yield, low price, favored by the majority of consumers. Drying is considered to be a common technology in the preservation and processing of agricultural and seafood. Moreover, some scholars have confirmed that pre-drying can reduce the oil absorption of food in the frying process.

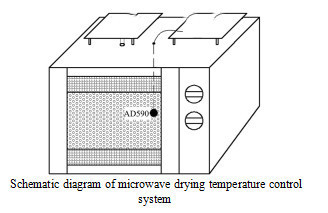

The traditional drying methods are mainly sunlight drying and hot air drying. The equipment used for hot air drying is less investment and the operation process is simple. However, hot air drying consumes a lot of energy and takes a long time to operate. It is easy to cause thermal damage and excessive oxidation of materials. Both methods have shortcomings in operation hygiene, processing efficiency and food quality control. As a new drying technology, microwave drying has been developed rapidly in recent years for its advantages of fast drying rate, clean and sanitary, and good controllability. However, its application in cereals, fruits and vegetables, oils and other materials has been less studied in aquatic products.

Microwave drying is obviously different from traditional drying. Traditional drying is through heat conduction, heat from the outside of the material into the inside, while microwave drying is generated by high frequency reciprocating movement of internal dipole molecules, which has fast heat transfer rate and high efficiency. Duan Zhenhua et al. found that lower microwave power was helpful to maintain the excellent quality of fillets after microwave drying of bighead carp and tilapia.

Using freshwater fish as raw material, fish fillets of various flavors have been developed by salting, boiling and baking. However, there are few reports on the drying of grass carp fillets by microwave drying. In this paper, the microwave drying law of grass carp fillets was studied, and compared with the hot air drying process. The experimental results were analyzed and fitted, and finally the best drying model was determined.