Study on Microwave Drying of Pleurotus eryngii and Optimization of Its Parameters

Absrtact: With drying time and color difference as indexes, microwave intensity, initial moisture content and slice thickness as experimental factors, orthogonal experiments were carried out to study the law of water loss in microwave drying of Pleurotus eryngii.

It was found that the moisture loss of microwave drying equipment for Pleurotus eryngii could be divided into two stages: heating and rapid water loss. The optimum microwave drying parameters for Pleurotus eryngii were 60% initial moisture content, 32 kW/kg microwave intensity and 3 mm slice thickness.

Key words: food processing; microwave drying of Pleurotus eryngii

Pleurotus eryngii, also known as Pleurotus eryngii, is a new rare edible fungus developed and cultivated successfully in recent years. Pleurotus eryngii Mushroom is a kind of edible mushroom with thick flesh, compact and even tissue, crisp and tender texture, pleasant almond fragrance and abalone taste. It is also a few edible mushroom species with crisper and smoother stalks than the mushroom cap. It is known as "Pleurotus ostreatus" and "dried shellfish mushroom".

The edible part of Pleurotus eryngii is 100%. It is rich in vitamin B, nicotinic acid, folic acid, pantothenic acid and various minerals. It contains 8 kinds of essential amino acids for human body. It has the functions of lowering blood lipid, blood pressure and cosmetology. It also has certain preventive and inhibitory effects on some tumors. It combines food, recuperation and therapy and is deeply loved by consumers.

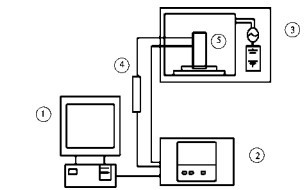

In this paper, the microwave drying of Pleurotus eryngii was studied, and its water loss law was explored. With drying time and color difference as indexes, microwave intensity, initial moisture content and slice thickness as experimental factors, orthogonal experiments were carried out to obtain the optimum parameters of microwave drying of Pleurotus eryngii, in order to provide technical guidance for fine control of drying process applied in production.