Effect of drying methods on quality characteristics of pomegranate powder

Abstract: in order to provide technical basis for large-scale production of pomegranate fruit powder, the quality characteristics of pomegranate fruit powder made by microwave drying equipment, vacuum freeze-drying and spray drying were analyzed and compared. The drying effect of maltodextrin, soluble starch and beta cyclodextrin as drying aid was compared.

The results showed that maltodextrin had the best drying effect, and the powder extraction rate (20%) of spray dried pomegranate fruit powder was higher (s), and the dispersing time (92 g) was shorter. The bulk density (0.30 g / mL) and moisture content (1.63%) were lower. Generally speaking, the quality of pomegranate fruit powder prepared by spray drying is better than that of pomegranate, which is beneficial to maintain the flavor and nutritional value of pomegranate.

Key words: microwave drying of pomegranate powder; drying method; quality characteristics

Pomegranate is a deciduous shrub or small tree of the genus Pomegranate of the family Pomegranate. It originated in Iran, Afghanistan and other areas. It is said that Zhang Qian was introduced into China when he was sent to the Western Regions in the Western Han Dynasty. Pomegranate fruit is rich in carbohydrates, proteins, many kinds of amino acids and essential elements such as K, Ca, Mg, Na, etc. In addition, it also contains trace elements such as Cu, Fe, Zn and many vitamins. Pomegranate contains 11%-14% sugar, 0.4%-1.0% fruit acid and 79% water. The content of vitamin C is 1-2 times that of apples and pears, which is very prominent in all kinds of fruits. Pomegranate seeds have many functions, such as resisting hunger and thirst, relieving drunkenness, promoting food production, detoxifying, antidiarrhea, anticancer and anti-aging.

Fruit powder is a kind of powder material made from various fruits after drying, dehydration and crushing. It not only keeps the original nutrients and flavor substances, but also is conducive to human digestion and absorption. In recent years, fruit powder has become one of the hotspots in fruit and vegetable processing because of its natural nutrition, easy to use, easy storage and transportation.

With the development of science and technology in food industry, the drying methods of fruits and vegetables are more and more, such as early natural drying, hot air drying, microwave drying, spray drying, vacuum freeze-drying, etc. Natural drying method is greatly influenced by human factors and natural conditions, and the quality of drying is difficult to guarantee. Hot air drying is the most commonly used drying method. Temperature gradient and moisture gradient change in reverse direction. The closer to the later stage of drying, the more difficult it is for material moisture to evaporate. The longer the drying time is, the greater the energy consumption is, and the drying speed of hot air is slower and the drying time is longer.

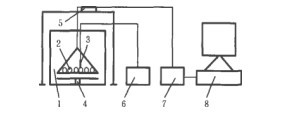

Microwave drying is a new drying method at present. The advantages of microwave drying are fast drying speed, uniform drying of materials, difficult crusting of materials in drying process, high energy utilization efficiency and less investment. The disadvantage is that if the operation is improper, the quality of materials after microwave drying is relatively low. Vacuum freeze-drying is a process of removing water or other solvents from frozen materials by sublimation. It has the characteristics of keeping the original activity, appearance, color and shape of products, fast dissolution of samples and low residual moisture. It is a drying method to obtain high-quality biological products.

Spray drying is most suitable for the processing of fruit and vegetable juice rich in heat sensitive nutrients. At the same time, because of the short heating time and low material temperature, the nutrients and flavor of fruits and vegetables are well preserved, and the granularity of products is small and even, which has good dispersibility and instant solubility. Therefore, spray dried products can directly drink and can be used as compound food ingredients, which has great advantages.

At present, pomegranate has been processed into juice, vinegar, fruit wine and other products, but there are few reports about pomegranate powder. In this study, pomegranate fruit powder was prepared by spray drying, microwave drying and vacuum freeze drying. Their physical properties were compared, and the best processing method of pomegranate powder was discussed, in order to provide theoretical basis and technical reference for the industrial production of pomegranate fruit powder.