Optimization of Microwave-Hot Air Combined Drying of Garlic Granules

Absrtact: In order to optimize the optimum technological parameters of Microwave-hot air combined drying garlic granules, garlic granules were used as test materials, and drying rate, garlic content, sensory score, whiteness, rehydration ratio and comprehensive score were taken as indicators. The effects of different microwave power density and different hot air temperature on the drying characteristics and quality of garlic granules were compared and studied, and microwave power density and conversion point dry base water were used. L orthogonal experiment was designed to optimize the drying conditions of garlic granules by Microwave-hot air combined drying.

Key words: garlic microwave drying; hot air drying; Microwave-hot air combined drying; Allicin

Garlic is a bulb of Allium in Liliaceae. It is rich in carbohydrates, proteins, fats, dietary fibers, vitamins, minerals and a variety of amino acids and vitamins. It has the functions of preventing and curing cardiovascular diseases, lowering blood lipids, preventing mutation, antioxidant, anti-cancer, anti-asthma, bacteriostasis and regulating immunity. It has broad market prospects in the fields of food, cosmetics and medicine. Garlic is prone to germination and mildew during storage, which is one of the bottlenecks restricting the development of garlic industry. Drying garlic is one of the main forms of garlic processing, which is conducive to consumption, long-term storage and subsequent processing.

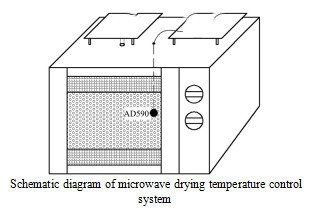

Microwave drying equipment has the advantages of high thermal efficiency, fast drying speed and no pollution, but its cost is high. Hot air drying is a widely used drying technology in garlic drying production. It has low energy consumption, easy operation and low cost, but its drying speed is slow and its quality is poor. Microwave-hot air combined drying can reduce drying energy consumption, improve drying rate and product quality. VA-RITH et al found that Microwave-hot air combined drying longan was golden yellow, which could shorten the drying time by 64.3% and reduce energy consumption by 48.2%.

TORRIN-GA et al considered that Microwave-hot air combined drying could improve the structure of Lentinus edodes with short drying time, good rehydration and lower shrinkage rate; REN et al. applied 60 W microwave combined with 40 C hot air drying American ginseng, could shorten drying time by 28.7%-55.2%, and had little effect on product color; GO-WEN et al. found that 210 W microwave combined with 160 C hot air drying chickpea rehydration. The shortest time, better organizational structure and color.

In addition, microwave combined hot air drying is also used in the drying of grapes, orange peel and instant boiled rice. These studies have proved that Microwave-hot air combined drying can improve the drying rate and ensure the quality of dried garlic, but the research on Microwave-hot air combined drying of garlic granules has not been reported.

There are two types of drying in series by microwave and hot air: one is combined drying by hot air and microwave, the other is combined drying by microwave and hot air. Preliminary experiments showed that garlic granules had high apparent viscosity and were easy to harden after drying by hot air-microwave combined drying, resulting in scorch and cracking deformation.

In order to find a suitable method for drying garlic granules, the effects of microwave, hot air and their combined drying on the drying characteristics, allicin content, rehydration ratio, whiteness and sensory evaluation of garlic granules were studied in this experiment. The combined drying process parameters of garlic granules were put forward to provide theoretical basis for garlic drying.