Effects of Different Drying Methods on Quality Characteristics of Purple Potato

Absrtact: In order to improve the quality of dried purple potato products, the effects of hot air drying, microwave drying equipment, vacuum drying and solar assisted heat pump combined drying on the physical and chemical properties and structure of dried purple potato were studied.

The results show that there are significant differences in energy consumption, color, functional ingredients, hardness and structure of products obtained by different drying methods. Microwave drying has the highest drying efficiency, but its color and structure are poor. Vacuum drying products have the highest retention rate of functional ingredients, but the lowest drying efficiency and the largest energy consumption. The products obtained by solar heat pump drying have the highest drying efficiency and energy consumption. The comprehensive performance of consumption, color and structure is the best, and the product quality is good.

Key words: purple potato microwave drying; physicochemical properties; tissue structure

Purple potatoes, also known as purple sweet potatoes and black potatoes, have purple to dark purple flesh. They are rich in anthocyanins, selenium and iron in addition to ordinary sweet potatoes, and have good nutritional and health functions. However, fresh purple potatoes harvested after harvesting are not able to withstand storage due to their high water content (65%-80%), perishability and deterioration, resulting in increased production and no increase in income, seriously affecting the economic benefits and production of growers. Enthusiasm.

Drying is one of the important means to solve the storage of food raw materials with high moisture content. It is also one of the most widely used unit operations in food production and processing. With the development and research of drying technology, different drying methods emerge, such as solar drying, heat pump drying, vacuum microwave drying, which provide a variety of options for food drying. At the same time, in the drying process, different drying methods will have a significant impact on the quality of food materials and their products.

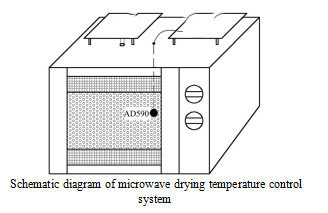

Therefore, it is urgent to find an efficient, energy-saving and green drying technology for the processing of purple potato. In this paper, the effects of solar assisted heat pump drying, hot air drying, microwave drying and vacuum drying on drying time, unit energy consumption, retention of anthocyanins, reducing sugar and carotenoids, as well as the color, hardness and microstructure of purple potato were compared. The drying characteristics of different drying methods were discussed in order to obtain better results. The best drying method of purple potato dried products was obtained, which provided theoretical basis and practical guidance for improving the quality of purple potato dried products.