Effect of Painless Drying Method on the Quality of Poria cocos

ABSTRACT: Objective To compare the effects of hot air drying, infrared drying, microwave drying and low temperature adsorption drying on the quality of Polygonum umbellatum. The drying rates of the four drying methods were compared. The rehydration and appearance of the dried products were tested and evaluated, and the total yellow pour content in the dried products was determined by ultraviolet spectrophotometry.

Result Microwave drying equipment had the fastest speed, and the product had better rehydration, while low temperature adsorption drying had advantages in flavonoid content retention and appearance color.

Key words: microwave drying of tuckahoe cocos; flavonoids; hot air drying; infrared drying; microwave drying; low temperature adsorption drying; ultraviolet spectrophotometry

Poria cocos is the root of Ilex glabrata, a liliaceous plant. Its taste, light, flat nature, return to the liver and intercalated meridians are commonly used Chinese herbs for clearing away heat and detoxification. It has the functions of regulating diarrhea, strengthening spleen and stomach, strengthening muscles and bones, removing dampness, and promoting joints. It is clinically used to treat limb constriction, muscle and bone pain caused by dampness and heat, hypoderma, scabies, syphilis and mercury poisoning. Recent studies have shown that Tufa cocos has anti-cancer, anti-atherosclerosis and treatment of coronary heart disease and other pharmacological effects.

There are many chemical constituents in Polygonum multiflorum, including volatile constituents, sterols, lipid-acid-proof, phenolic glycosides and yellow constituents. The main active ingredients are yellow substances.

The drying method of tufa cocos in the process of collecting and processing is the factor affecting the quality and medicinal efficacy of tufa cocos. In this experiment, hot air, infrared, microwave and low temperature adsorption drying were carried out on tufa Cocos slices, and the flavonoid content, rehydration test and appearance evaluation of the dried products were carried out, and various drying methods were comprehensively analyzed and compared.

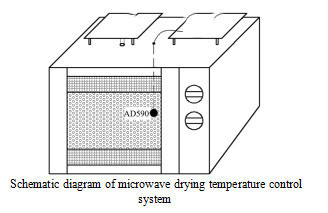

Because of high drying temperature and long drying time, the loss of flavonoid content in Poria glabra was the greatest among four drying methods, and the appearance of the dried products was also the greatest. Infrared drying has shorter drying time and higher drying rate, but it is inferior to microwave and low temperature adsorption drying in maintaining its nutritional and appearance quality, only better than hot air drying. Microwave drying takes the shortest time and is second only to cryogenic adsorption drying in other qualities. However, the application of microwave drying technology in our country started late, and the application field is narrow. The instantaneous mass transfer and heat transfer theory of microwave drying is not mature enough.

Low temperature adsorption drying is more conducive to maintaining the drying quality and pharmacodynamics of Poria cocos. It can basically maintain the appearance of the material, and the effect of rehydration is the best. However, due to the lower drying temperature, the equipment consumes more energy and the drying time is longer. Considering from all aspects, low temperature adsorption drying is more suitable for dehydration and drying of materials with high added value and thermal sensitivity. Microwave drying is also an ideal drying method because of its short drying time and uniform heating. The results showed that microwave drying and low temperature adsorption drying were both ideal methods for drying tufa Cocos slices.