Effect of drying methods on physicochemical properties of wet konjac flour

ABSTRACT: In this study, the effects of hot air drying, vacuum heating drying and microwave drying on the physical and chemical properties of wet konjac flour were compared and analyzed, and the related mechanism was discussed.

The results showed that three drying methods had significant effects on the physical and chemical properties of konjac flour (p < 0.05). Compared with microwave drying equipment and hot air drying, the konjac flour obtained by vacuum heating drying has white color, the highest porosity, a large number of micro-holes formed in the interior, which makes the swelling rate of konjac flour the highest and the viscosity of the sol the highest (34500 mPa. s). The swelling property of konjac flour is better than that of other two drying methods, and is more suitable for drying konjac flour.

Key words: drying method, microwave drying of konjac flour, swelling property

Konjac glucomannan is the main chemical constituent of konjac flour (> 75%, w/w). It can form a high viscosity sol after swelling (it can absorb water equivalent to 80-100 times its own volume). As food, KGM can not only reduce weight, but also reduce cholesterol, regulate metabolism and enhance immunity.

In addition, KGM sol after water absorption and swelling can also exhibit gelation, thickening, film formation, suspension and other functions. Therefore, konjac powder is widely used in food, medicine, chemical industry, textile, petroleum and other fields.

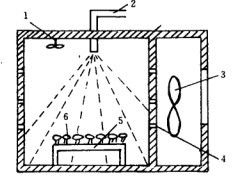

Drying is a necessary step in the production of wet konjac flour. Hot air drying, microwave drying and vacuum heating drying are three commonly used drying methods in food industry. The three drying methods have different drying mechanism, and the structure and morphology of drying materials are also different, which makes the physical and chemical properties of products different.

At present, there is no report on the effect of drying methods on the physical and chemical properties of wet konjac flour. The effects of three drying methods, hot air, microwave and vacuum heating, on the physical and chemical properties of konjac concentrate powder were studied with the porosity, bulk density, color, microstructure, viscosity and swelling rate as indicators, and the related reasons were analyzed in order to provide appropriate technical reference for wet konjac concentrate powder drying.

The swelling of konjac flour is a process in which KGM and water molecules form macromolecule sol through hydrogen bonding, molecular dipole and instantaneous dipole. The swelling properties of konjac flour depend not only on the composition of KGM molecule, i.e. the content and polarity of polar components, but also on the structure of granules, such as porosity (density), pore structure (penetrating, semi-enclosed and enclosed), and pore size.

Generally speaking, under the condition of stable composition, the larger the porosity, the smaller the density, the larger the specific surface area of the material and the shorter the course of water migration within the material, the faster the water absorption and swelling speed and the shorter the time.

The structure of granular cells in vacuum-heated drying keeps good, there are a lot of pore on the surface and inside, and the granule absorbs water quickly, which makes KGM swell quickly and has high viscosity. Because of the shrinkage degree of the drying process and the compact structure, it is difficult to rehydrate the product, so that the swelling rate and viscosity of granular powder are lower than those in vacuum. Heating and drying products.

Microwave dried fine powder products have higher porosity, but lower swelling rate and viscosity. This may be related to the irreversible destruction of cell tissues and KGM caused by the high temperature inside the particles during microwave drying.