Research and Application of Drying Technology of Raw Material Drug Slag

Absrtact: Before burning streptomycin residue, the moisture content of the residue should be reduced to 20%. Microwave dryer, rotary flash dryer, soft granulator and vertical plate dryer were used to dry streptomycin residue.

The experimental results show that the two-stage drying technology of raw material drug bacterial residue by pelletizer and tray dryer is advanced, which can meet the requirement of moisture content for incineration treatment of bacterial residue after drying. However, the control of drying time of steam content in the drying process of each kind of bacterial residue needs to be further explored.

Key words: API; streptomycin; bacterial residue; drying technology; two-stage drying of soft granulator and vertical plate dryer; microwave drying of traditional Chinese medicine

Huasheng North China Pharmaceutical Company mainly produces streptomycin and dihydrostreptomycin in two production lines. Streptomycin and dihydrostreptomycin are filtered by ceramic membrane and centrifuge respectively. The filtrate is collected and extracted. The filtrate is filtered by plate and frame to form a bacterial residue or mud with 80% water content. The output is 30 t/d.

Streptomycin residue is characterized by strong stickiness. The fermentation broth residue is clearly defined as hazardous waste in the National Dangerous Waste List, which is classified as HW02. According to the requirements of environmental protection, it can only be incinerated, landfill or other treatment, and can not be sold, transported or stored.

Huasheng Pharmaceutical Company of North China adopts incineration treatment method. Before incineration, the moisture content of bacterial residue can be reduced to less than 20% by drying method, which is the key to achieve the incineration standard, and reducing the moisture content of bacterial residue is the key before incineration.

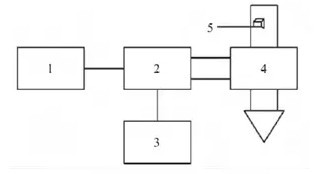

Huasheng Pharmaceutical Company of North China adopts two-stage drying form of granulator and plate dryer to dry bacterial residue of API. Because the moisture content of bacterial residue of API is high and the stickiness of bacterial residue is high, it needs to undergo several steps of dewatering treatment to reduce the moisture content to less than 20% in a more energy-saving way.

The results show that the first step is to reduce the moisture content to less than 75% through the plate and frame filter press, then maximize the specific surface area of the bacterial residue through the soft granulator, and enter the plate dryer for drying, to obtain the finished product drying bacterial residue.

The actual production for more than one year proves that the drying system can fully meet the production needs.

However, because Huasheng produces many kinds of raw materials and medicines, and the properties of bacterial residues are different, the control of steam flow and drying time are also different. In the future, the control of drying process of each kind of bacterial residue will be further studied.