Research progress of combined drying technology for conditioned fruit and vegetable products

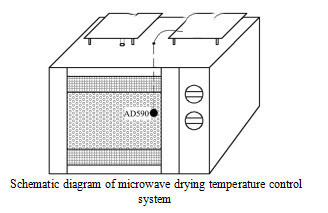

Absrtact: Microwave drying equipment can make full use of the characteristics of each drying mode and optimize the drying process complementarily, so as to improve product quality, increase economic efficiency, safety and environmental protection, and reduce the energy consumption of drying.

In this paper, the previous studies on combined drying of fruits and vegetables were summarized and analyzed comprehensively. The main types of combined drying and the research status of combined drying at home and abroad were introduced. Finally, the problems and development trend of combined drying technology of fruits and vegetables were analyzed.

Key words: fruit and vegetable microwave drying; combined drying technology; research progress

China is a big fruit and vegetable country. With the upgrading of consumption structure, the market demand for fruit and vegetable conditioning is growing. The proportion of fruit and vegetable is increasing day by day, and the drying technology of fruit and vegetable is also developing and progressing. From the original traditional natural drying, shade drying to today's infrared drying, freeze-drying, microwave drying and so on, there are many kinds of fruit and vegetable.

However, these single drying technologies have some shortcomings, such as high energy consumption, low efficiency, poor product quality and so on. In recent years, people's consumption concepts have gradually changed. They are no longer simply concerned about price, but more about taste and quality. They need to conform to health, safety and style. The drying method with low consumption, high efficiency and high quality has become a research hotspot.

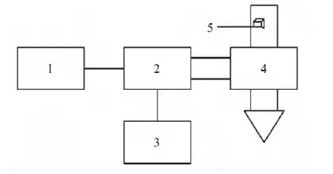

At present, the combination drying technology is the most widely used in fruit and vegetable drying, which combines two or more drying technologies. Combination drying technology can enhance advantages and avoid disadvantages, complement each other's single drying shortcomings, and magnify the advantages. According to the material characteristics of conditioned fruits and vegetables, the appropriate drying methods are selected to combine drying to achieve low energy consumption and high efficiency process to obtain high-quality products.

There are many kinds of combined drying technology, which can be divided into microwave correlation combined drying, far infrared correlation combined drying, heat pump correlation combined drying, osmosis correlation combined drying and so on. In this paper, the application and research status of combined drying in conditioned fruit and vegetable processing were summarized. In addition, the future application of combined drying technology in conditioned fruit and vegetable processing was prospected. In order to provide reference for the future development of fruit and vegetable processing industry.

With the upgrading of the consumption structure of Chinese residents, the consumption of products tends to be more of a quality requirement. Conditioning the processing and drying of fruits and vegetables is a way to improve the added value of fruits and vegetables. Different single drying methods have their respective advantages and disadvantages. Two or three drying methods are combined to achieve the minimum energy consumption, the highest efficiency and the best quality products.

At present, the research of drying technology is more inclined to shorten drying time, improve drying efficiency and save energy. There are few studies on the mechanism of heat and mass transfer during drying, the degradation kinetics model of main nutrients and the optimum storage conditions of dried products.

Many combinatorial drying methods are only experimental studies, and have not been applied to industrial production and processing on a large scale. In the future, combined drying will gradually improve the mechanism of heat and mass transfer in combined drying process. At the same time, the dynamics of nutrient loss in drying process should be strengthened to maximize the nutritional value of the product.