Microwave drying equipment for oil-free instant noodles

For a long time, most instant noodles sold on the market are fried instant noodles. The production of fried instant noodles needs a large amount of imported brown oil. On the other hand, the oil content of fried instant noodles is difficult to control, generally high. However, the production of oil-free instant noodles usually adopts hot air drying thousand. The quality of instant noodles produced by this processing method is poor, such as dry shrinkage, poor rehydration, dark appearance and so on. For this reason, the WC135L-1 microwave drying equipment has been developed by our institute with the cooperation of Henan Central Plains Industry and Trade Company.

Characteristics of microwave drying equipment for instant noodles

Conventional heating methods, such as electric heating, steam, hot air, etc., are used to transfer heat through convection and conduction. The heat transfer mode is from the surface of the object to the interior, so the speed is slower. Microwave heating is carried out by the movement of polarized molecules of matter under the action of high electromagnetic field. It is a kind of medium heating. The processed material is heated both inside and outside at the same time. Therefore, the heating is uniform, fast and the thermal efficiency is high. It improves the efficiency by 2-4 times compared with the conventional heating method, and the maximum temperature difference does not exceed 5C.

Easy to control, easy to automate continuous production, because microwave power, transmission speed can be stepless adjustment, there is no problem of thermal inertia in conventional heating. Reaction speed is fast and can be controlled in real time, so it is suitable for different process parameters and their adjustment. It greatly reduces the rate of waste products and inferior products.

The equipment is small and easy to install. It is 1/3~1/4 of the far infrared and hot air drying equipment with the same function.

The quality of instant noodles processed by microwave is greatly improved compared with that processed by conventional methods. The noodles are full in block shape, good in rehydration, good in color and taste, smooth and elastic, continuous in rehydration and not muddy in soup. At the same time, it also has the function of disinfection and sterilization, which greatly prolongs the shelf life of instant noodles and food safety and hygiene.

The equipment is a tunnel type box heater with continuous transmission processing. Its main body is composed of many metal square boxes. From the point of view of microwave technology, it is a rectangular multi-mode resonator. Microwave electron tube (mainly continuous wave magnetron) excites electromagnetic oscillation of some working modes in the box through coupling device, and produces thermal effect through the interaction between electromagnetic field and product material, so as to achieve the purpose of heating and drying.

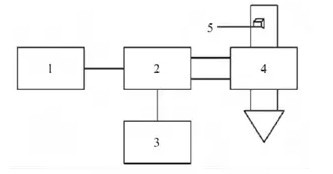

In order to ensure that the heating chamber has good technical performance and technical and economic indicators, careful design and calculation must be carried out, and repeated tests and adjustments must be made through instruments and tests to make its performance meet the practical requirements of the equipment using five WY2 L microwave sources. The microwave source consists of magnetron, high voltage direct current source, filament power supply and magnetic field power supply of electromagnet. Magnetron is the heart of microwave source, and microwave is produced by it. In order to improve the efficiency of the whole machine and eliminate the surface moisture of the dough, a hot air drying section is added after the microwave equipment.

With multi-layer transmission, the structure of automatic temperature control and the maximum temperature can reach 120 C. The finalization and transmission of surface blocks are also important components and technical keys. Because no metal is allowed to enter the microwave field, it is necessary to use materials with low microwave loss and temperature resistance and not easy to deform to make face boxes. Tetraethylene is one of the ideal materials. In order to ensure the reliability of the transmission system and the accuracy of the box entry, metal chains must be used for transmission, which can easily cause abnormal phenomena such as strong reflection of electromagnetic wave and fire. After careful design, the problem was finally solved.