Effects of Different Drying Technologies on the Quality of Lonicera macranthoides

ABSTRACT: Objective To investigate the effects of different drying methods on the quality of Lonicera macranthoides. METHODS Lonicera macranthoides was processed by shade drying, sun drying, drying, microwave drying equipment, vacuum drying and far infrared drying, and its appearance was observed. The content of chlorogenic acid in Lonicera macranthoides was determined by HPLC. Results The appearance of vacuum dried samples was good, and the content of chlorogenic acid was high, which was obviously better than that of other drying methods. CONCLUSION The method is sensitive, accurate and reproducible. It can be used for the processing and quality control of Lonicera macranthoides from Sichuan province.

Key words: Lonicera macranthoides microwave drying; drying method; microwave drying; vacuum drying; far infrared drying; medication quality; chlorogenic acid; high performance liquid chromatography

Lonicera macranthoides is a dry bud or first-blooming flower of Lonicera macranthoides, which has the functions of anti-bacterial, anti-inflammatory, cooling and dispersing wind-heat, clearing away heat and detoxifying toxins. It is mainly used to treat such diseases as carbuncle, larynx arthralgia, heat-poisoning hemorrhoea, wind-heat cold and warm-fever. It is known as penicillin in traditional Chinese medicine.

Lonicera macranthoides is widely distributed in Sichuan, Hunan and Guizhou provinces. It is rich in resources. Sichuan Province has resource advantages. The content of chlorogenic acid in Lonicera macranthoides from Sichuan is obviously higher than that of Lonicera japonica and Lonicera japonica from Shandong and Henan, but its price is lower than that of the latter two. The main reason is that the traditional drying method is used mostly by the pharmaceutical farmers in the processing of producing areas, which is not only inefficient, but also difficult to control the internal quality.

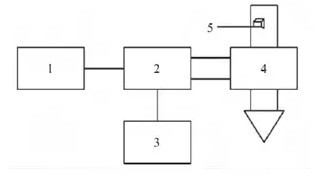

Therefore, it is an important technical link to control the operation points of drying methods to ensure the quality and properties of finished products. In this paper, Lonicera macranthoides is used as raw material in Yibin, Sichuan Province. Six drying methods, shade drying, sun drying, drying, microwave drying, vacuum drying and far-infrared drying, are used to process Lonicera macranthoides. Observing the appearance characteristics of processed samples, then determining the content of chlorogenic acid in samples by HPLC, and comparing the advantages and disadvantages of different drying methods can provide experimental basis for improving and controlling the quality standard of Lonicera macranthoides.

Ultrasound extraction with 50% methanol (2.706%), 75% methanol (2.822%) and pure methanol (2.993%) was compared. The results showed that the higher the concentration of methanol, the higher the extraction rate. However, if pure methanol was used as solvent, it would cause great waste of resources and environmental pollution in industrial production. Therefore, 75% methanol was chosen.

In addition, different ultrasonic extraction time was investigated, in which Lonicera macranthoides was completely extracted at 45 minutes. The sulfur fumigation processing method was also investigated. The samples obtained had good appearance and luster, but had a strong sulfur odor. Some literatures also mentioned that after sulfur fumigation, the content of characteristic components of honeysuckle has been reduced to varying degrees, which directly affects the medication quality of honeysuckle.

In the GAP standard of Chinese medicinal materials, this method has been forbidden to be used in the processing technology of Chinese medicinal materials. The effects of different light intensity on the appearance and the content of chlorogenic acid in Lonicera macranthoides were also investigated. It was found that the effect of light intensity on the appearance of Lonicera macranthoides was insignificant under full illumination, but the content of its active ingredients was higher than that measured under other light intensity. This will be the next step of the study.